50

50

TROUBLESHOOTING

FAULT

PROBABLE CAUSE

REMEDY

Drill Press Does

Not Run

Wrong voltage

Emergency switch has been

pressed.

Electrical enclosure door

malfunction.

Safety guard malfunction

because of the limit switch.

Limit switch faulty

Stop button was pressed.

Make sure the machine voltage

matches the nameplate.

Turn E-Stop switch clockwise (cw) to

reset. Wait 10 sec. for the Delta motor

controller to reset. Push the start

button.

Make sure door is closed properly and

switched to ON (locked) position.

Make sure limit switch actuator is in the

center detent position.

Replace limit switch.

Wait 10 sec. for the Delta motor

controller to reset. Push the start

button.

Excessive

Vibration

Improper belt tension.

Uneven belt wear. (hard spots)

Motor or spindle pulley out of

balance.

Bad motor.

Adjust belt tension.

Replace belt.

Balance or replace problem pulley.

Replace motor.

Motor Stalls

Over feeding.

Dull drill or tap.

Motor not building up to running

speed.

Bad motor

Reduce feed rate.

Sharpen drill & keep sharp.

Replace or repair motor.

Replace motor.

Noisy Operation

Noisy spline.

Lubricate spline.

WARNING:

Make sure the electrical disconnect is OFF before working on

the machine.

Содержание DP-1000VS

Страница 19: ...16 16 OVERALL DIMENSIONS ...

Страница 20: ...17 17 GETTING TO KNOW YOUR MACHINE Q F P J B C A G H I L M E F D N O K R ...

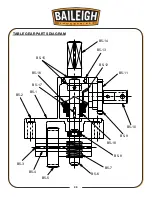

Страница 35: ...32 32 A6 2 A6 3 A6 1 A6 4 A8 1 A8 2 A5 A5 1 A33 1 A19 1 A33 ...

Страница 36: ...33 33 A20 7 A30 A17 2 A17 1 A17 A18 A18 1 A30 1 A20 9 A20 8 A9 1 A9 2 A20 6 A31 A32 A31 1 A20 5 A20 4 A20 2 ...

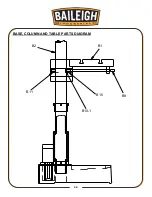

Страница 39: ...36 36 BASE COLUMN AND TABLE PARTS DIAGRAM B1 B2 B11 B10 B9 B10 1 ...

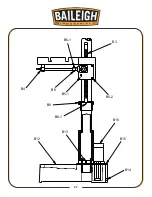

Страница 40: ...37 37 B3 B4 B6 1 B6 B5 1 B5 2 B8 B8 1 B12 B13 B16 B15 B14 ...

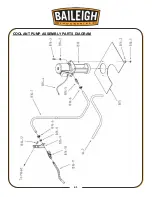

Страница 44: ...41 41 COOLANT PUMP ASSEMBLY PARTS DIAGRAM ...

Страница 46: ...43 43 CONTROL PANEL PARTS DIAGRAM ...

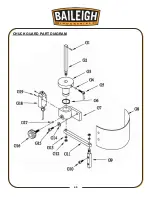

Страница 48: ...45 45 CHUCK GUARD PART DIAGRAM ...

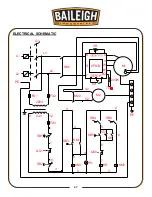

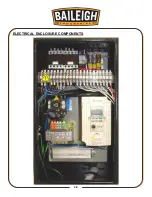

Страница 51: ...48 48 ELECTRICAL ENCLOSURE COMPONENTS ...