Installation and Operation Manual

Document #9620-20-b-mc-16 base tool changer-07

Pinnacle Park

•

1031 Goodworth Drive

•

Apex, NC 27539

•

Tel: 919.772.0115

•

Fax: 919.772.8259

•

www.ati-ia.com

•

Email: [email protected]

B - 10

4. Maintenance

4.1 Preventive Maintenance

The Tool Changer and optional modules are designed to provide a long life with regular

maintenance.

A visual inspection and preventative maintenance schedule is provided in the table below

depending upon the application. Details are provided in

Section 8—Drawings

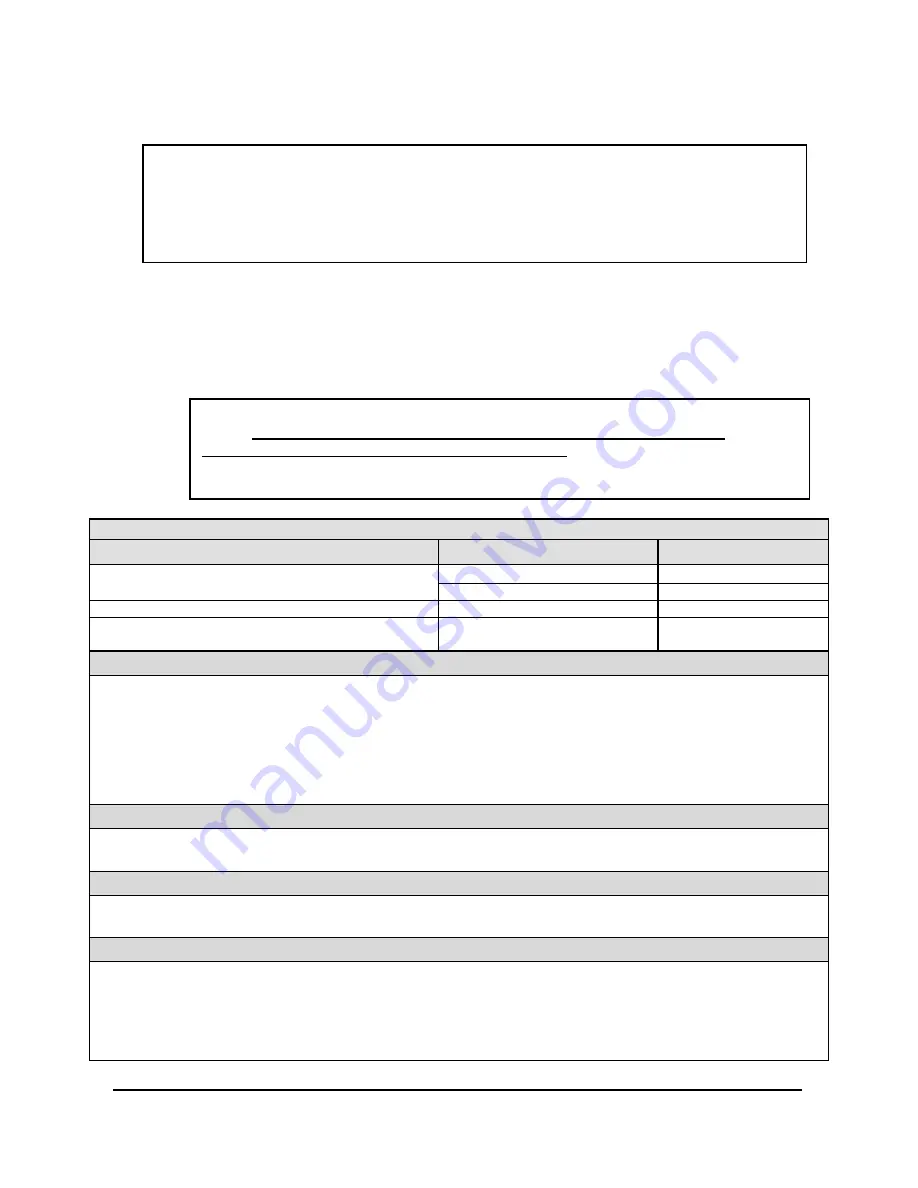

Table 5.1 —Preventative Maintenance Checklist

Application(s)

Tool Change Frequency

Inspection Schedule

General Usage, Material Handling, Docking Station

More than 1 per minute

Weekly

Less than 1 per minute

Monthly

Wet or Humid Environments

All

Weekly

Welding/Servo/Deburring, Foundry Operations

(Dirty Environments)

All

Weekly

Locking Mechanism Cam and Alignment Pins

□

Inspect for lubrication and wear. A NLGI #2, lithium-based grease with molybdenum disulfide additive is suggested

for locking mechanism and alignment pin lubrication. Over time, lubricants can become contaminated with process

debris. Therefore, it is recommended to thoroughly clean the existing grease and replace with new as needed.

Refer to

Section 4.2—Locking Mechanism, Alignment Pins Cleaning and Lubrication

□

Excessive alignment pin/bushing wear may be an indication of poor robot position during pickup/drop-off. Adjust

robot position as needed. Check Tool Stand for wear and alignment problems. Refer to

Section 4.3—Alignment

Mounting Fasteners and Interface Connections

□

Inspect for proper torque and interference or wear, abrasions, cuts of hoses, and electrical cables. Tighten and

correct as required.

O-rings and Rubber Bushings

□

Exposed o-rings and rubber bushings may be subject to damage during normal operation. Inspect for wear,

abrasion, and cuts. Replace damaged o-rings and rubber bushings as needed.

Electrical Module

□

Clear debris from area of the contact using compressed air. Do not directly clean contacts as abrasion may occur

and the performance of the contact may be compromised. Inspect Electrical Contacts for wear or damage. Refer

to

Section 4.4—Electrical Module Pin Block Contact Inspection and cleaning.

□

Inspect V-Ring Seal for wear, abrasion, and cuts. Refer to

Section 4.5—Electrical Module Seal Inspection and

NOTICE:

All Tool Changers are initially lubricated using

MobilGrease® XHP222 Special

grease. The end user must apply additional lubricant to the locking mechanism

components and alignment pins prior to start of service (See Section 4.2). Tubes of

lubricant for this purpose are shipped with every Tool Changer. Note:

MobilGrease®

XHP222 Special

is a NLGI #2 lithium complex grease with molybdenum disulfide.

NOTICE:

The cleanliness of the work environment strongly influences the trouble-free operation

of the changer. The dirtier the environment, the greater the need is for protection against debris.

Protection of the entire EOAT, the Master, the Tool, and all of the modules may be necessary.

Protective measures include the following: 1) placement of Tools Stands away from debris

generators, 2) covers incorporated into the Tool Stands [see Section 2.3] and 3) guards,

deflectors, air curtains, and similar devices built into the EOAT and the Tool Stand.