ARITERM SWEDEN AB

Installation, Operation & Maintenance -

2009.02.18- 18/32

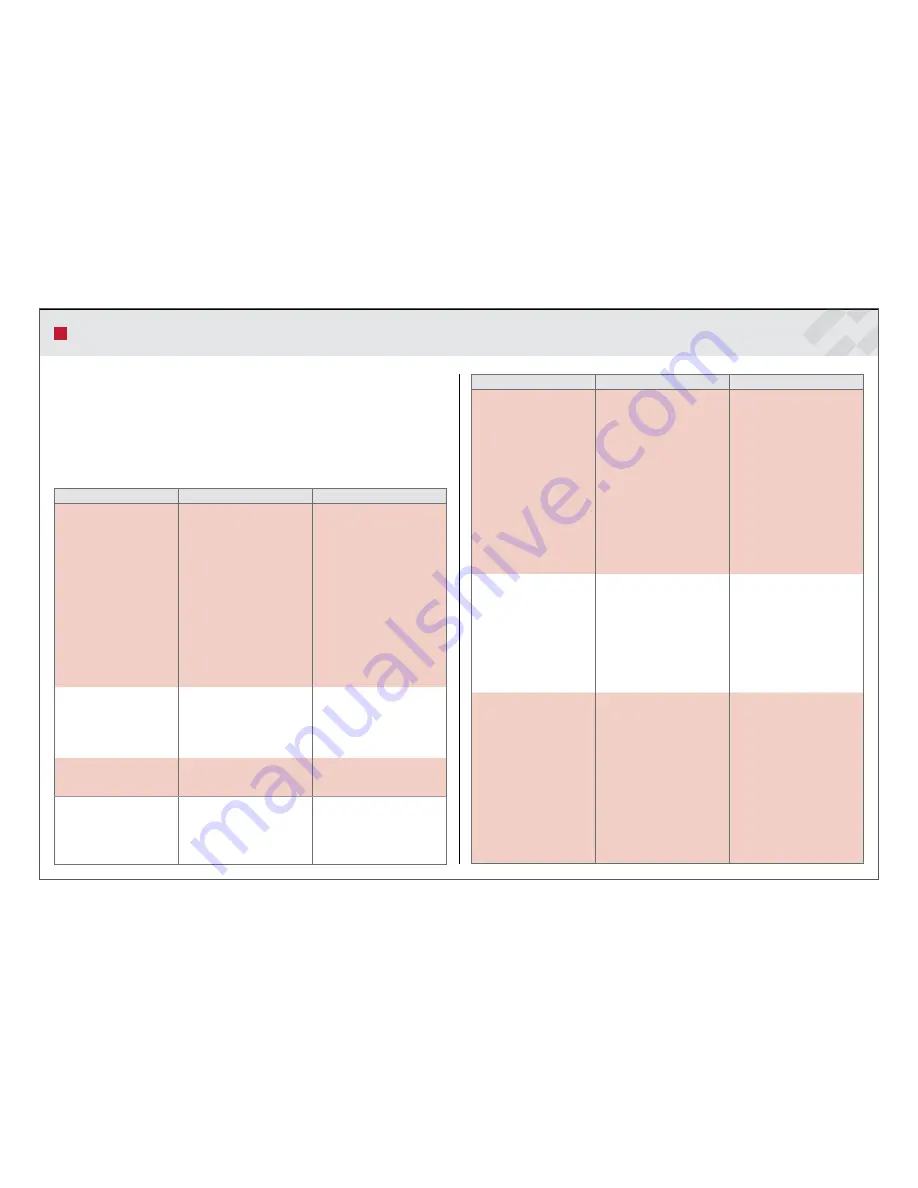

TROUBLESHOOTING

Problem

Check

Remedy

All display segments are out.

that the fuses of the control unit of the

burner are intact and the main switch

has been turned ON.

has the over-temperature protection

tripped?

Replace the defective fuse in the cont-

rol unit or turn ON the power by me-

ans of the main switch. Note! Discon-

nect the device from electricity supply

before replacing the fuse. The size of

fuses F1 and F2 is 4A/230 V.

If the cause of over-heating cannot be

determined with certainty, contact an

authorised technician. If the over-tem-

perature protection of the boiler has

tripped, put it back into operation by

pressing the RESET button. After this

switch the control unit OFF and then

back ON. Also check that the 3-phase

current is correctly connected.

The red operation indication is on.

The display reads:

ALARM PELLETS NO

.

The burner is requesting fuel, but

has not received it.

that there are pellets in the fuel sto-

rage.

Add pellets.

that the inclination of the drop pipe is

not too gentle.

Shake the drop tube and change the

inclination so that pellets will not get

stuck.

that the inclination of the external au-

ger is not too steep (max 45°) or feeding

of fuel has not stopped, because pellets

have been stuck in the silo.

Adjust the auger into a more gentle

angle and turn it back and forth a few

times so that the pellets come loose.

The feed opening of fuel must be loca-

ted in the middle of the fuel store (app-

lies to small week stores).

In case an alarm becomes active, this is indicated on the display of the control panel

with a red light and a text message. This facilitates troubleshooting, because the user

can see the cause of the problem. The alarm is acknowledged by selecting OFF on the

control unit. The cause of the alarm must always be determined and the problem re-

moved before the device is switched on again.

The following checks and remedies are described in such an order that the most pro-

bable cause of the problem is given first.

Problem

Check

Remedy

that the motor shaft rotates the auger

and the motor of the external auger

operates.

(In most cases the default setting of the

operating time of the external auger (30

seconds) is not long enough to bring suf-

ficient amount of pellets to the burner. If

the problem cannot be removed by me-

ans of the above checks and remedies,

the operating time of the external auger

may be too short. In such cases increase

the operating time (see page 15, menu 3

-> ”Auger external time”). However, the

operating time must not be so long that

pellets accumulate into the drop tube.)

If the motor does not rotate, disconnect

the power cable from the boiler and

connect it directly to a mains socket by

means of the additional cable provided.

If the motor has been over-heated due

to a blockage or for some other

reason, the over-temperature protec-

tion of the motor may have been trip-

ped. The motor will not start until it has

been cooled down. Also check that the-

re are no blockages in the auger.

If there are problems with the motor,

contact an authorised technician.

The red operation indication is on

and the display reads:

ALARM MAX THERMOSTAT

, or

ALARM MAX THERMOSTAT

ELECTRIC

The over-temperature protection of

the boiler has tripped.

has the over-temperature protection

tripped?

check the circulation pump.

If the cause of over-heating cannot be

determined with certainty, contact an

authorised technician. If the over-tem-

perature protection of the boiler has

tripped, put it back into operation by

pressing the RESET button. After this

switch the control unit OFF and then

back ON. Also check that the 3-phase

current is correctly connected.

The red operation indication is on

and the display reads:

CONTROL EL. IGNITION

or

CONTROL OPTICAL MONITOR

The cause of the problem is that

the optical flame monitoring of

the burner has not detected flame

during a certain period of time. No

fuel has entered into the combus-

tion head.

that the flame guard and/or the com-

bustion head is not full of ash and

the flame guard has not over-heated

or sooty.

Remove ash, clean the combustion

head from loose ash and wipe the

flame guard clean. If the flame guard

becomes easily sooty, the cause may

be incorrect settings or too low under-

pressure in the furnace. In such cases

call a technician.

Содержание Biomatic plus 50

Страница 10: ...ARITERM SWEDEN AB Installation Operation Maintenance 2009 02 18 10 32 WIRING DIAGRAM ...

Страница 25: ...ARITERM SWEDEN AB Installation Operation Maintenance 2009 02 18 25 32 FEEDING SYSTEM DEPO FEEDO 606 mm 1500 mm ...

Страница 27: ...ARITERM SWEDEN AB Installation Operation Maintenance 2009 02 18 27 32 MANUFACTURES DECLARATION ...

Страница 28: ...ARITERM SWEDEN AB Installation Operation Maintenance 2009 02 18 28 32 NOTES ...

Страница 29: ...ARITERM SWEDEN AB Installation Operation Maintenance 2009 02 18 29 32 NOTES ...

Страница 30: ...ARITERM SWEDEN AB Installation Operation Maintenance 2009 02 18 30 32 NOTES ...