SECTION 5 – INSTALLATION INSTRUCTIONS

UL EX3470 ULC EX3470

PAGE 5-4 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

INSTALLING THE DISTRIBUTION PIPING

Before the following procedures can be completed, the piping

design must already be determined; and the actuation and

expellant gas lines from the regulated release, each regulated

actuator, and each tank-enclosure or tank-bracket assembly

should already be installed.

These installation instructions are identical for single, double,

and multiple-tank systems except for the quantity of tanks and

hazard areas to be covered.

General Piping Requirements

1. Use Schedule 40 black iron, chrome-plated, or stainless

steel pipe and fittings.

NOTICE

Do not use hot-dipped galvanized iron

pipe or fittings in the agent distribution

piping.

2. Before assembling the pipe and fittings, make certain all

ends are carefully reamed and blown clear of chips and

scale. Inside of pipe and fittings must be free of oil and dirt.

3. The distribution piping and fitting connections, located in or

above the hood or the protected area, must be sealed with

pipe tape. When applying pipe tape, start at the second

male thread and wrap the tape (two turns maximum) clock-

wise around the threads, away from the pipe opening.

NOTICE

Do not allow tape to overlap the pipe

opening as the pipe and nozzles could

become plugged.

Thread sealant or compound must not be

used as it could plug the nozzles.

4. Distribution piping may be run independently or two agent

tanks may be manifolded together and run to the prede-

termined hazard area. Only agent tanks expelled from the

same cartridge may be manifolded.

NOTICE

Closely follow the piping requirements

for each size system, as detailed in the

“System Design” section, when installing

distribution piping.

5. Branchline tees can be used to create more than one

branch and can be installed as a thru tee, side outlet tee or

bull tee.

Pipe Hanger Recommended Guidelines

1. Space hangers as follows:

Maximum Recommended

Pipe Size

Distance Between Hangers

3/8 in.

5 ft (1.5 m)

2. Hangers should be placed between elbows when the

distance is greater than 2 ft (0.6 m).

Piping Installation

1. Starting at the tank, pipe directly from the union located on

the tank adaptor. A reducing fitting may be necessary to

conform to the distribution piping.

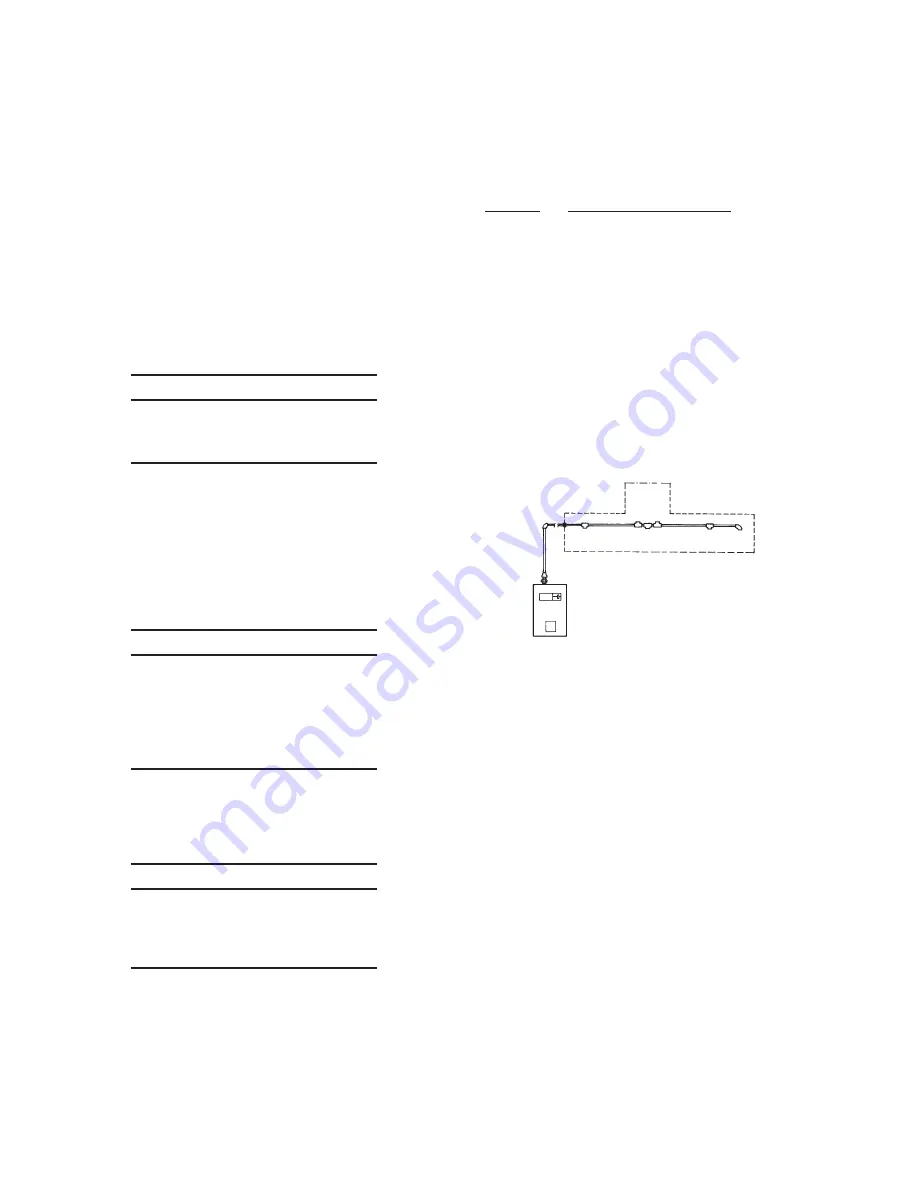

2. Based on the piping sketch developed in the “System

Design” section of this manual, install the supply line and

position the tees at points where branch lines must be

installed. See Figure 5-7.

3. Run all branch lines to the hazard area and connect each

nozzle. (Make certain all piping is securely bracketed.)

FIGURE 5-7

000302

4. Make certain all threaded connections are properly tight-

ened. Threaded connections located in the protected

area(s) and above the hood must be sealed with Teflon

pipe tape, as a minimum. Apply pipe tape to male threads

only. Make certain tape does not extend over the end of the

thread, as this could cause possible blockage of the agent

distribution.

Pipe tape minimizes friction between bearing surfaces of

the threads when threading pipe to fittings. The resulting

heat may expand the pipe threads before the joint is prop-

erly made. When the pipe threads cool and contract in

the fitting, the joint may become loosened causing cooking

grease to migrate into the distribution piping, and/or leakage

at the fitting during a pressure test or agent discharge.

Note: When required to provide pressure testing of pipe

or a system discharge test, it is recommended that all pipe

connections utilize Teflon pipe tape.

5. Install the correct nozzle(s) for each hazard area as previ-

ously designed. Some nozzles are required to be properly

oriented before they are positioned for aiming.