September 2012

L010194

11

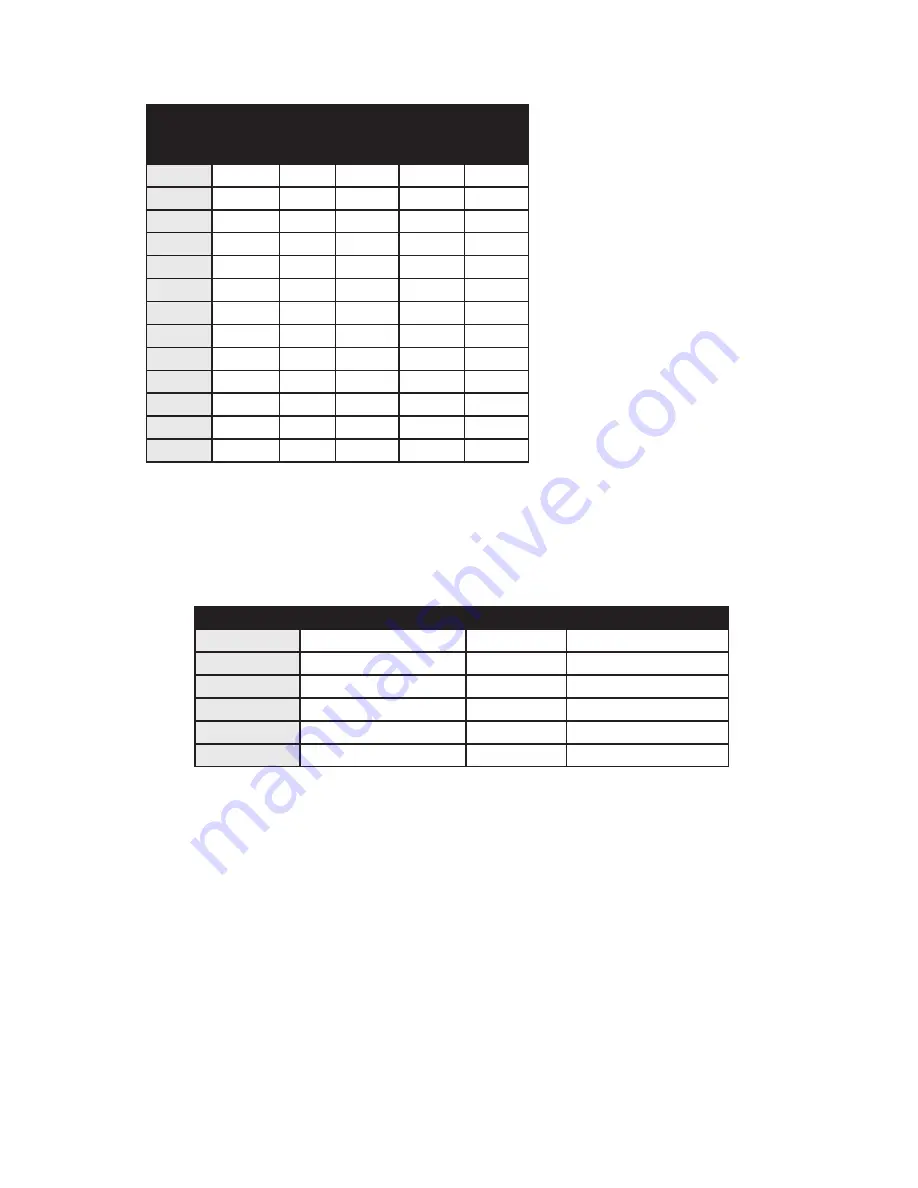

Step Motor Selection Guide

Anaheim Automation offers motor cable, making hookups quickly and easy! Contact the

factory of visit our website www.anaheimautomation.com for motor and cable offerings.

Part

Number

Unipolar

Rating

Series

Peak

Rating

Parallel

Peak

Rating

Series

Current

Setting

Parallel

Current

Setting

23Y206

3.0A

3.0A

6.0A

60%

100%

23Y210

5.0A

5.0A

10.0A

100%

100%

23Y306

3.0A

3.0A

6.0A

60%

100%

23Y310

5.0A

5.0A

10.0A

100%

100%

34Y108

4.0A

4.0A

8.0A

80%

100%

34Y207

3.5A

3.5A

7.0A

70%

100%

34Y307

3.5A

3.5A

7.0A

70%

100%

23Y108

4.0A

4.0A

8.0A

80%

100%

23Y106

3.0A

3.0A

6.0A

60%

100%

23Y104

2.0A

2.0A

4.0A

40%

80%

17Y302

---

1.0A

---

22%

---

17Y202

---

1.0A

---

22%

---

17Y102

---

1.0A

---

22%

---

Setting the Output Current

The output current on the DPC50501 is set by an onboard potentiometer. This potentiometer deter-

mines the per phase peak output current of the driver. The relationship between the output current

and the potentiometer value is as follows:

Reducing Output Current

Reducing the output current is accomplished by setting switch 1 of the DIP switch to the ON position

and occurs approximately 20mSec after the last positive going edge of the step clock input. The

amount of current per phase in the reduction mode is approximately 50% of the set current. When

the current reduction circuit is activated, the current reduction resistor is paralleled with the current

adjustment potentiometer. This lowers the total resistance value, and thus lowers the per phase

output current.

Determining Output Current

The output current for the motor used when microstepping is determined differently from that of a full/half

step unipolar driver. In the DPC50501, a sine/cosine output function is used in rotating the motor. The

output current for a given motor is determined by the motors current rating and the wiring configuration of

the motor. There is a current adjustment potentiometer used to set the output current of the DPC50501.

This sets the peak output current of the sine/cosine waves. The specified motor current (which is the

unipolar value) is multiplied by a factor of 1.0, 1.4, or 2.0 depending on the motor configuration (series,

half-coil, or parallel).

Peak Current Potentiometer Setting Peak Current Potentiometer Setting

0.5A

0%

3.0A

60%

0.6A

10%

3.5A

70%

0.9A

20%

4.0A

80%

1.5A

30%

4.5A

90%

2.0A

40%

5.0A

100%

2.5A

50%

--

July 2018