CIP Axis Attributes

Chapter 4

Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018

447

1.

Switch to Stopping state.

2.

Apply "Current Decel" or "Ramp Decel" method to stop motor.

3.

Wait for zero speed or 'Stopping Time Limit' or a factory set timeout,

whichever occurs first.

4.

Deactivate Mechanical Brake output to engage brake.

5.

Wait for "Mechanical Brake Engage Delay" while brake engages.

6.

Perform (optional) Brake Proving operation to verify brake control of load.

7.

Disable inverter power structure.

8.

Transition to Stopped state.

9.

Deactivate Resistive Brake contactor to disconnect motor from inverter

power structure.

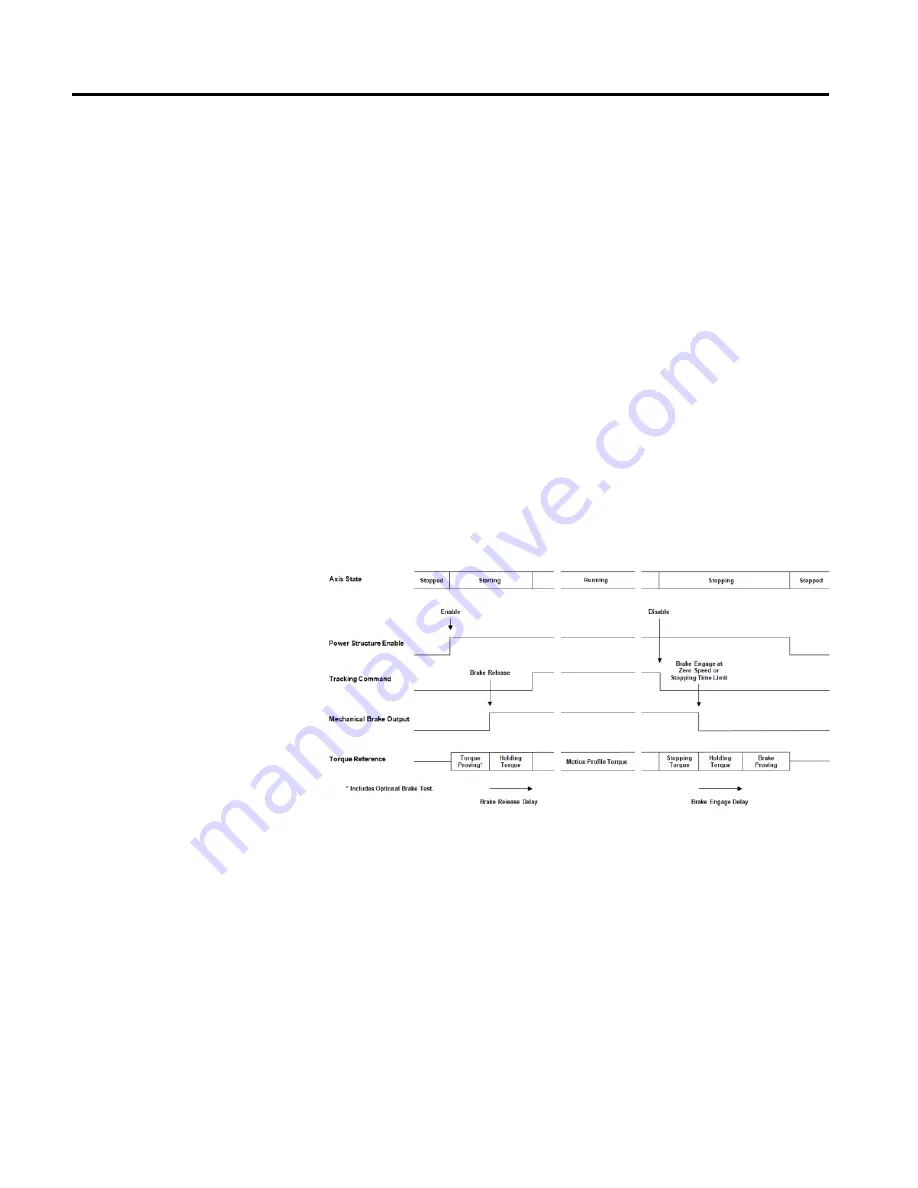

The following diagram illustrates a Category 1 Stop Sequence:

Category 2 Stop Sequence

Torque is applied to stop the motor and inverter is left enabled to provide holding

torque. The mechanical brake is not used. Brake Proving is not applicable. A

Category 2 Stop is only allowed in no Start Inhibit condition is present.

1.

Switch to Stopping state.

2.

Apply "Current Decel" or "Ramp Decel" method to stop motor.

3.

Wait for zero speed or "Stopping Time Limit" or a factory set timeout,

whichever occurs first.

Содержание Kinetix 5500

Страница 10: ......

Страница 86: ......

Страница 470: ......

Страница 496: ...Index 496 Rockwell AutomationPublicationMOTION RM003I EN P February 2018 D device functioncodes 96 E exceptions 496 ...