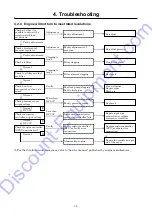

4. Troubleshooting

4-9

※

For the detailed countermeasures, refer to “Service manual” published by engine manufacturer.

4.2.10

Purge control operation will not start even if AUTO IDLE (purge control)

switch is pressed

※

As the output voltage of intake negative pressure sensor at unload operation is very little, it is better

to check the function of purge control operation after replacing the sensor with new one, if it is found

difficult to diagnose the trouble.

Lower than

15

%

Faulty setting of purge

operation load factor (b)

15

%

10sec

No air leak

Service air piping leaking

Air leak

Faulty setting of the time

required for switching to

purge operation (T)

Set time is

too long

Adjust (See 1.6.2)

Check AUTO IDLE switch

wire connection

Disconnection or faulty

contact between emergency

controller

-

auto idle

switch

-

ground

Wire

disconnected

Repair wire connection

Trouble of intake negative

pressure sensor

Abnormal

output

voltage found

Replace it

Not wire

disconnected

Key ON when stopping

:

DC0.5V

At unload

:

Less than DC0.5V

At no load:

Not electrically

connected

Repair or replace it

Repair wire connection

Trouble of emergency

controller

Repair or replace it

At no load:

Electrically connected

Normal

Disconnection or faulty

contact between emergency

controller and intake

negative pressure sensor

Wire

disconnected

Repair wire connection

Not wire

disconnected

※

Check service piping for

any air leak

Check setting of purge

operation load factor (b)

Check setting of the time

required for switching to

purge operation (T)

Check intake negative

pressure sensor output

voltage of “Key ON when

stopping” and “At unload”

(See 3.12)

Check wire connection

between intake negative

pressure sensor and

emergency controller

Check electrical connection

to solenoid valve for

starting unloader / purge

Trouble of solenoid valve

for starting unloader /

purge

Abnormal (Short-circuit etc.)

Check wire connection between emergency

controller and solenoid valve for starting

unloader / purge

Abnormality compressor

air-end

Disassemble / check

Repair

Check the pressure

difference before and after

oil separator equipped

Differential

pressure is

large

Normal

Faulty oil separator

Replace it

19.3

-

21.4psi

(98.1

-

147kPa)

[0.98

-

1.47bar]

Adjust (See 1.6.2)

Repair air piping

Discount-Equipment.com

Содержание PDS185S-6E1

Страница 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m...

Страница 9: ...1 Specification 1 3 1 3 Outline Drawing Unit in A131026 D i s c o u n t E q u i p m e n t c o m...

Страница 10: ...1 Specification 1 4 Unit mm A131025 D i s c o u n t E q u i p m e n t c o m...

Страница 18: ...1 Specification 1 12 1 7 Piping Diagram PC14063E D i s c o u n t E q u i p m e n t c o m...

Страница 19: ...1 Specification 1 13 1 8 Fuel Piping PC14001 D i s c o u n t E q u i p m e n t c o m...