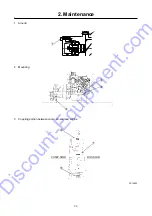

2. Maintenance

2-13

2.9

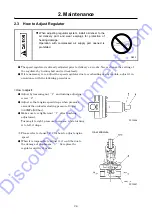

Change of Pellet assembly of By-pass Valve

●

By-pass valve fitted on this unit is of full bore type. While the unit is used for normal operation, it

is not to perform periodical replacement of the inner pellet assembly, but when such trouble as

excessive rise of compressor oil temperature, it becomes necessary to replace it, in accordance

with the following procedures.

<Procedure>

①

First stop the unit and make sure that there is no residual pressure left in the separator receiver

tank.

②

After checking and confirming that the temperature of compressor oil has become amply low,

open drain valves on separator receiver tank and oil cooler to empty compressor oil completely.

③

After draining compressor oil, remove bolt

“

1

”

and then the pellet assembly

“

2

”

of the by-pass

valve and O-ring

“

3

”

.

④

Replace the pellet assembly

“

2

”

and O-ring

“

3

”

by new ones. Install O-ring

“

3

”

coated thinly with

compressor oil.

⑤

Supply compressor oil through the filler port provided on the receiver tank.

(Refer to instruction manual)

⑥

Start operation and check the function of by-pass valve.

(It functions well when delivery air temperature will not rise abnormally.)

PC14009E

Actuating temperature

By-pass valve fully closing temperature

180

±

37°F (82

±

3

℃

) 192

±

36°F (89

±

2

℃

)

To oil filter

(when the oil

temperature

is low)

To oil cooler

(when the oil

temperature

is high)

From separator

receiver tank

1

3 2

Discount-Equipment.com

Содержание PDS185S-6E1

Страница 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m...

Страница 9: ...1 Specification 1 3 1 3 Outline Drawing Unit in A131026 D i s c o u n t E q u i p m e n t c o m...

Страница 10: ...1 Specification 1 4 Unit mm A131025 D i s c o u n t E q u i p m e n t c o m...

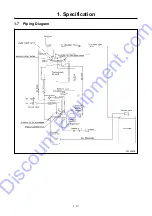

Страница 18: ...1 Specification 1 12 1 7 Piping Diagram PC14063E D i s c o u n t E q u i p m e n t c o m...

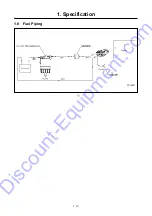

Страница 19: ...1 Specification 1 13 1 8 Fuel Piping PC14001 D i s c o u n t E q u i p m e n t c o m...