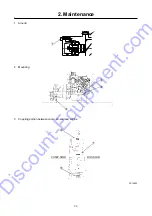

2. Maintenance

2-7

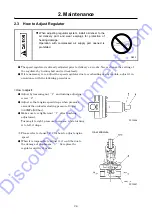

A130967

2.4

Change of Element in Fuel Pre-filter

<Procedure>

①

Turn fuel selector valve

“

1

”

to

“

OFF

”

position.

②

Loosen the drain valve

“

2

”

and drain out condensed

water inside.

③

Turn the cup

“

3

”

to the left and remove it. Be careful

to remove the cup

“

3

”

because it is filled with fuel.

Wipe out split fuel completely.

④

Remove float

“

4

”

inside cup

“

3

”

.

⑤

Washing element

“

5

”

and the cup inside with new

fuel.

⑥

Replace element

“

5

”

and O-ring if they are found

broken or damaged.

⑦

After finishing clean, assemble it in reverse

procedure.

●

If air is found still in fuel pipe, place starter switch to

“RUN”

position and loosen air bleeding bolt

“

6

”

to

bleed air. After finishing air bleeding, tighten the air

bleeding bolt

“

6

”

.

●

Drain the condensate in container, and then dispose

of condensate according to the designated

regulations.

[Tightening torque of cup

“

3

”

]

: 239

-

292lbf

・

in(27

-

33N

・

m)[280

-

340kgf

・

cm]

ON

5

1

6

OFF

4

2

3

Removal Installation

Discount-Equipment.com

Содержание PDS185S-6E1

Страница 1: ...www discount equipment com D i s c o u n t E q u i p m e n t c o m...

Страница 9: ...1 Specification 1 3 1 3 Outline Drawing Unit in A131026 D i s c o u n t E q u i p m e n t c o m...

Страница 10: ...1 Specification 1 4 Unit mm A131025 D i s c o u n t E q u i p m e n t c o m...

Страница 18: ...1 Specification 1 12 1 7 Piping Diagram PC14063E D i s c o u n t E q u i p m e n t c o m...

Страница 19: ...1 Specification 1 13 1 8 Fuel Piping PC14001 D i s c o u n t E q u i p m e n t c o m...