Locking device

SA14 SA24

SA10

SA23

SA21

Fig. 50d.

Fig. 50c.

TC_00148

TC_00148

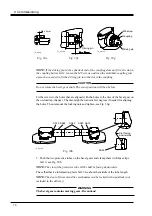

2. Put the square shaft, protective tubes and hose clips according to Fig. 50b.

Fig. 50b.

Fig. 50a.

SA11

SA11

SA13

A

SA11

A

TC_00178

TC_00148

SA12

9 Commissioning

9.2.5 Mounting of the Horizontal Drive Shaft

1. Dismantle the locking device from the bevel gear on the diverter switch housing.

75

CAUTION

Assembly with the on-load tap-changer and the motor-drive mechanism in different

operating positions may cause a transformer break down.

3. Connect the square shaft with the mounted coupling halves to the shaft of the bevel

gear, see Fig. 50c. Mount two coupling halves SA11 to the other end of the square

shaft and the shaft of the other bevel gear. Push the shaft to the bottom of the

fitting in the coupling halves. Tighten the screws lightly and check that the shaft

not can be moved more than 2 mm in axial direction (axial play). Tighten the

screws A first and thereafter the other, see Fig. 50d.

4. The motor-drive mechanism and the on-load tap-changer should have the same

indicated tap position and be in their

exact

positions.

The motor-drive mechanism and on-load tap-changer are in the same position

when the position indicators in both of them show the same position, see Fig. 39.

The motor-drive mechanism is in

exact

position since section 9.2.2 has been

carried out.

The on-load tap-changer is in

exact

position when the window where the

position is read in the bevel gear is facing the red point in the gear box housing

exactly, see Fig. 39.

If the gear box is not in its exact position, loosen the two screws in the multihole

coupling on the gearbox and find the position of the screws that positions the

opening in the brass toothed wheel closest to the red point in the gear box housing.

The maximum deviation from exact alignment is given in Fig 39. Tighten the

screws.