14

Required for work

according to chapter/section

n

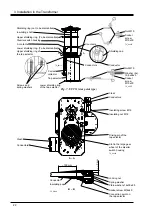

Wooden block as spacer

3.3

n

Grease (ball bearing grease) GULF-718 EP,

Mobil-Grease 28, SHELL-Aero Shell Grease 22 or similar

3, 9.2.2

n

Oil, see section 1.4

6

n

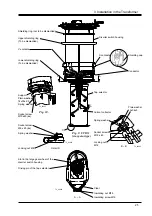

Dimension drawing for the on-load tap-changer for

6

connection dimensions of the oil valve

n

Flange for connection to the oil conservator flange

6.4

when filling under vacuum, see Fig. 45

n

Two oil valves for connection to flange with dimensions

6.4.1

according to Fig. 45. Can be ordered from ABB

n

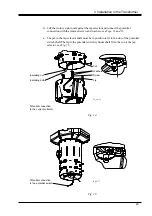

Equipment for oil filling

6

n

Sealing tape

6.3

n

Maintenance Guide for UCC/UCD

7.2

n

Circuit diagram for the motor-drive mechanism

7.2

n

Oil filter (in case of common conservator for both the

5.5

transformer and the on-load tap-changer) can be ordered

from ABB.

1.4 Oil

The oil quality should be of Class II according to IEC publication 296.

Table 1. Weight of oil in kg.

Type designation

Oil weight

1)

UCC.. 380/...., UCD.. 380/....

700

UCC.. 650/...., UCD.. 650/....

760

UCC.. 1050/....,UCD.. 1050/....

860

1)

The oil for the conservator is not included.

WARNING

Do not energize the transformer until oil has been filled according to chapter 6, Oil

Filling, in this guide.

1.5 Oil Conservator

The on-load tap-changer has to be connected to an oil conservator. ABB recommends

to use a separate conservator for the on-load tap-changers with both oil and air side

separated from the main conservator of the transformer.

1 Introduction