56 Guidelines for planning the electrical installation

Selecting the control cables

Shielding

All control cables must be shielded.

Use a double-shielded twisted pair cable for analog signals. ABB recommends this type of

cable for the pulse encoder signals also. Employ one individually shielded pair for each

signal. Do not use common return for different analog signals.

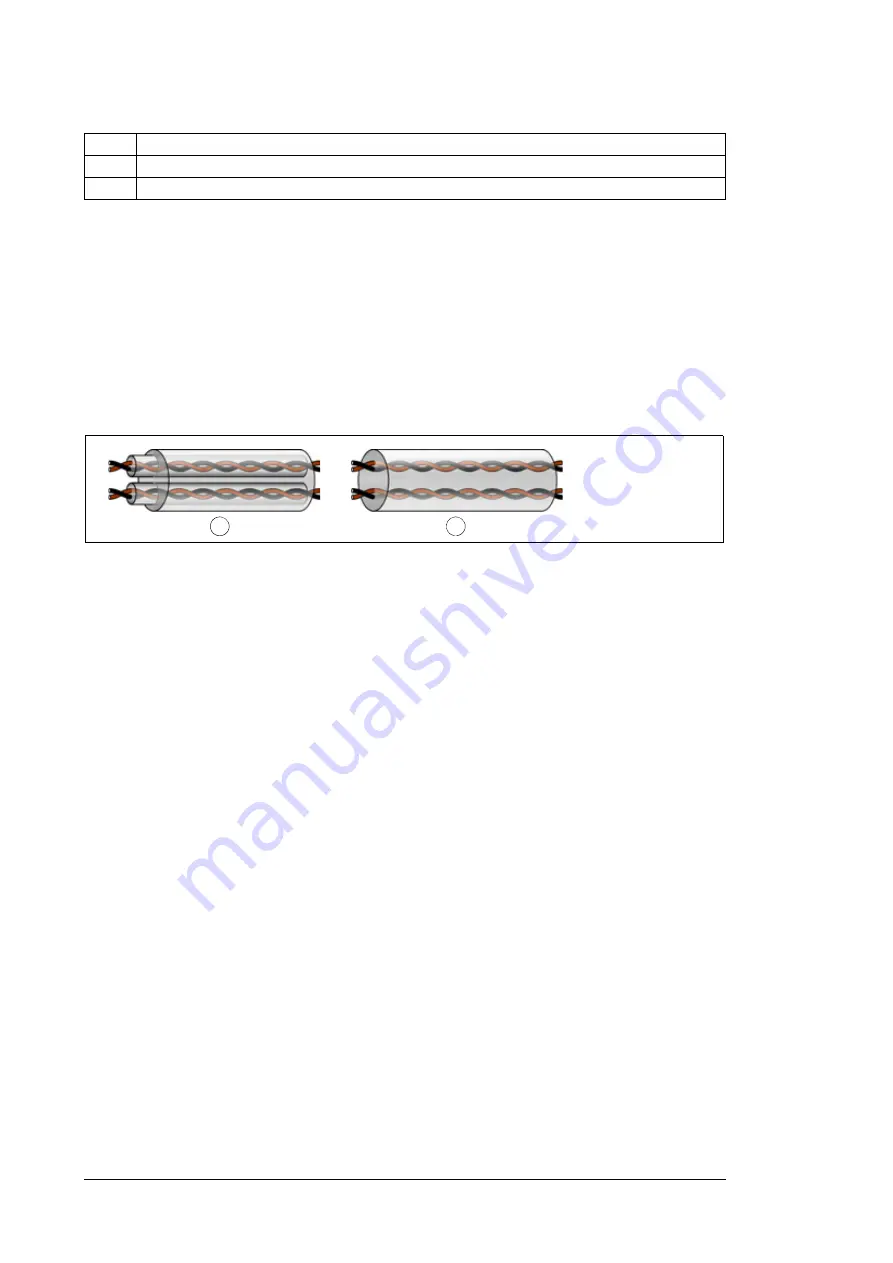

A double-shielded cable (figure a below) is the best alternative for low-voltage digital

signals but single-shielded (b) twisted pair cable is also acceptable.

Signals in separate cables

Run analog and digital signals in separate, shielded cables. Never mix 24 V DC and

115/230 V AC signals in the same cable.

Signals allowed to be run in the same cable

Relay-controlled signals, the voltage of which does not exceed 48 V, can be run in the

same cables as digital input signals. The relay-controlled signals should be run as twisted

pairs.

Relay cable type

The cable type with braided metallic screen (for example ÖLFLEX by LAPPKABEL,

Germany) has been tested and approved by ABB.

Control panel cable length and type

In remote use, the cable that connects the control panel to the drive must not be longer

than three meters (10 ft). Cable type: shielded CAT 5e or better Ethernet patch cable with

RJ-45 ends.

Routing the cables

Route the motor cable away from other cable routes. Motor cables of several drives can be

run in parallel installed next to each other. Install the motor cables, input power cables and

control cables on separate trays. Avoid long parallel runs of motor cables with other cables

in order to decrease electromagnetic interference caused by the rapid changes in the drive

output voltage.

Where control cables must cross power cables, arrange them at an angle as near to 90

degrees as possible. Do not run extra cables through the drive.

3

Copper wire screen

4

Inner insulation

5

Cable core

a

b

Содержание ACS580-07-0495A-4

Страница 1: ...ABB general purpose drives Hardware manual ACS580 07 drives 250 to 500 kW ...

Страница 4: ......

Страница 8: ...4 Update notice ...

Страница 16: ...12 ...

Страница 24: ...20 Safety instructions ...

Страница 42: ...38 Operation principle and hardware description ...

Страница 74: ...70 Electrical installation PE PE 8 PE 13 11 7 8 12 13 ...

Страница 82: ...78 Electrical installation ...

Страница 102: ...98 Fault tracing ...

Страница 114: ...110 Maintenance R10 and R11 4 5 2 7 6 3 8 ...

Страница 115: ...Maintenance 111 R10 and R11 9 10 ...

Страница 116: ...112 Maintenance R10 and R11 11 ...

Страница 117: ...Maintenance 113 R10 and R11 12b 12a ...

Страница 118: ...114 Maintenance R10 and R11 R10 and R11 17 14 13 R11 15 16 ...

Страница 126: ...122 Technical data Input and motor cable terminal dimensions of frame R10 Bottom entry and exit ...

Страница 127: ...Technical data 123 Input and motor cable terminal dimensions of frame R11 Bottom entry and exit ...

Страница 134: ...130 Technical data ...

Страница 137: ...Dimension drawings 133 13 Dimension drawings Example dimension drawings are shown below ...

Страница 138: ...134 Dimension drawings Frames R10 and R11 IP42 ...

Страница 139: ...Dimension drawings 135 Frames R10 and R11 IP54 option B055 ...

Страница 140: ...136 Dimension drawings ...

Страница 152: ...148 Safe torque off function ...

Страница 174: ...Contact us www abb com drives www abb com drivespartners 3AXD50000032622 Rev A EN 2016 03 16 ...