2

6

• Place

the

general

differential

circuit

breaker

to

"OFF"

position.

If

the

temperature

drops

below

0°C

there

is

serious

danger

of

frost:

add

a

mixture

of

water

and

glycol

in

the

system,

otherwise

drain

the

hydraulic

circuits

of

the

system

and

of

the

heat

pump.

11

MAINTENANCE

AND

PERIODICAL

CONTROLS

WARNING:

All

the

operations

described

in

this

chapter

HAVE

TO

BE

CARRIED

OUT

BY

TRAINED

STAFF

ONLY.

Before

any

operation

or

before

entering

the

inner

components

of

the

unit,

be

sure

that

the

power

supply

is

disconnected.

The

compressor’s

heads

and

discharge

piping

are

usually

at

high

temperature

levels.

Be

very

careful

when

operating

in

their

surroundings.

Aluminium

coil

fins

are

very

sharp

and

can

cause

serious

wounds.

Be

very

careful

when

operating

in

their

surroundings.

After

maintenance

operations,

re

‐

install

the

cover

panels,

and

fix

them

by

means

of

screws.

The

refrigerant

circuits

must

not

be

filled

with

different

gas

other

than

that

indicated

on

the

nameplate.

The

use

of

a

different

refrigerant

can

cause

severe

damage

to

the

compressor.

It’s

forbidden

to

use

oils

other

than

those

specified

in

this

manual.

The

use

of

a

different

oil

can

cause

serious

damage

to

the

compressor.

It

is

a

good

rule

to

carry

out

periodic

checks

in

order

to

verify

the

proper

operation

of

the

unit.

OPERATION

1

month

4

month

6

month

Filling

the

water

circuit.

x

Presence

of

bubbles

in

the

water

circuit.

x

Check

out

that

safety

and

control

devices

work

correctly

x

Check

out

possible

oil

leakage

from

compressor.

x

Check

out

possible

water

leakages

from

the

hydraulic

circuit.

x

Check

out

the

proper

working

of

the

flow

switches.

x

Check

out

that

the

crankcase

resistances

are

properly

supplied

and

functioning.

x

Clean

the

metallic

filters

of

the

hydraulic

circuit.

x

Clean

the

finned

coil

by

means

of

compressed

air

or

water

jet.

x

Check

out

that

all

the

terminals

on

the

electric

board

as

well

as

on

the

terminals

of

the

compressor

are

properly

fixed.

x

Tightening

of

water

connections.

x

Check

out

the

tightening

and

the

balancing

of

the

fan

blades.

x

Correct

voltage.

x

Correct

absorption.

x

Check

the

refrigerant

charge.

x

Check

the

operating

pressure,

and

superheat

and

subcooling

x

Check

of

the

efficiency

of

circulation

pump.

x

Check

the

expansion

tank.

x

If

the

unit

should

be

out

of

service

for

a

long

period,

discharge

water

from

the

piping

and

from

heat

exchanger.

This

operation

is

necessary

if,

during

seasonal

stoppages,

ambient

temperature

is

expected

to

go

down

below

the

freezing

point

of

the

employed

fluid.

x

11.1

ENVIRONMENTAL

PROTECTION

According

to

the

norms

dealing

with

the

use

of

depleting

stratospheric

ozone

substances,

it

is

forbidden

to

release

refrigerants

fluids

in

the

atmosphere.

They

have

to

be

collected

and

delivered

to

the

seller

or

to

proper

gathering

points

at

the

end

of

their

operating

life.

Refrigerant

R410A

is

mentioned

among

controlled

substances

and

for

this

reason

it

has

to

be

subjected

to

the

mentioned

norms.

A

particular

care

is

recommended

during

service

operations

in

order

to

reduce

as

much

as

possible

any

refrigerant

loss.

12

WHEN

THE

UNIT

GOES

OUT

OF

SERVICE

Once

the

unit

is

arrived

at

the

end

of

its

life

cycle

and

needs

to

be

removed

or

replaced,

the

following

operations

are

recommended:

• the

refrigerant

has

to

be

recovered

by

trained

people

and

sent

to

proper

collecting

centre;

• compressors’

lubricating

oil

has

to

be

collected

and

sent

to

proper

collecting

centre;

• the

frame

and

the

various

components,

if

not

serviceable

any

longer,

have

to

be

dismantled

and

divided

according

to

their

nature,

particularly

copper

and

aluminium,

which

are

present

in

conspicuous

quantity

in

the

unit.

These

operations

allow

easy

material

recover

and

recycling

process,

thus

reducing

the

environmental

impact.

Содержание HPE Series

Страница 21: ......

Страница 29: ...28 ...

Страница 31: ...30 16 WATER PUMP CURVES 16 1 MODELS HPE 06 09 16 2 MODELS HPE 12 15 ...

Страница 34: ...33 19 3 HPE 12 15 IN OUT 1 M ...

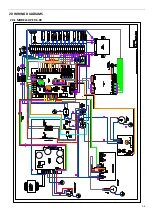

Страница 35: ...34 20 WIRING DIAGRAMS 20 1 MODELS HPE 06 09 ...

Страница 36: ...35 20 2 MODEL HPE 12 ...

Страница 37: ...36 20 3 MODEL HPE 15 ...

Страница 43: ...NOTE ...

Страница 44: ...NOTE ...

Страница 45: ...NOTE ...

Страница 46: ...NOTE ...

Страница 47: ......