Troubleshooting

Guide

22|

Page

5)

Slowly

re

‐

open

the

manual

gas

valve.

Check

to

see

that

there

are

no

gas

leaks.

6)

Open

some

of

the

fixtures

that

use

the

highest

flow

rate

to

activate.

7)

Check

the

inlet

gas

pressure.

Appropriate

pressures

are

listed

in

the

specification

page

at

the

front

of

this

manual.

PURGE

THE

GAS

LINE

OF

AIR:

1)

The

unit

should

not

be

running

during

this

procedure.

Turn

off

power

to

the

unit.

2)

Turn

the

gas

valve

to

the

off

position

(perpendicular

to

the

gas

line).

3)

Loosen

the

gas

line

on

the

unit

side

of

the

gas

valve

(at

a

flare

fitting

or

union).

4)

Next

open

the

gas

valve

very

slightly

until

you

can

smell

gas

by

wafting

the

air

towards

your

nose.

This

means

any

air

previously

in

the

gas

line

has

been

removed

and

only

gas

remains.

5)

Turn

gas

back

off

and

re

‐

tighten

gas

line.

6)

Turn

gas

back

on

and

check

for

leaks.

Spray

water

&

dish

soap

mixture

onto

fittings.

No

bubbles

means

there

are

no

leaks.

CHECKING

MANIFOLD

GAS

PRESSURE:

1)

Ensure

the

unit

is

not

in

operation.

2)

Remove

the

screw

off

the

manifold

port.

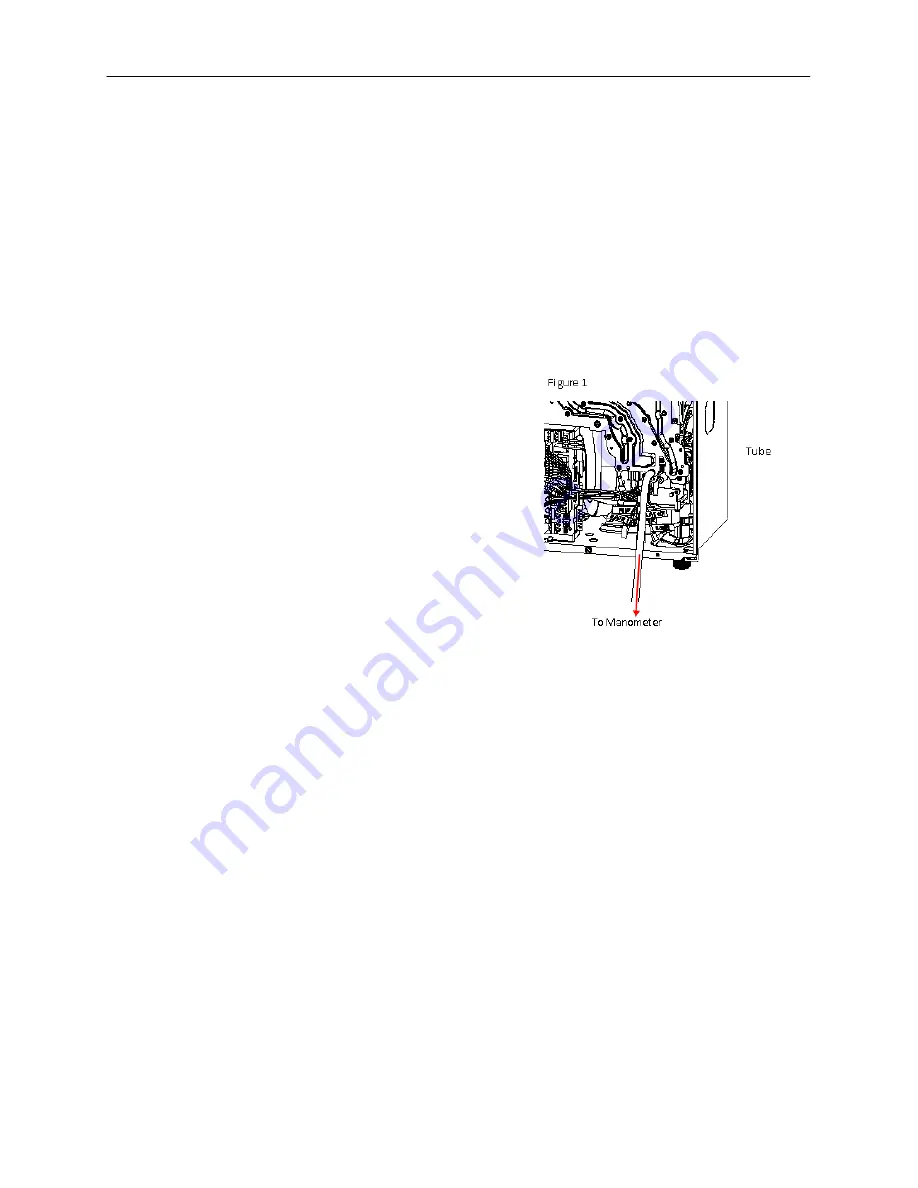

3)

Connect

a

manometer

to

the

manifold

port

using

a

tube

(Figure

1).

Ensure

that

this

connection

is

secure

enough

to

prevent

gas

leak.

4)

Run

water

through

the

unit

to

activate

its

operation.

It

is

suggested

that

a

large

amount

of

flow

is

drawn

in

order

to

prevent

overheating

during

max

burn.

If

presence

of

a

gas

leak

is

detected,

immediately

shut

off

the

unit

and

inspect

the

tube/manifold

connection;

otherwise,

proceed

onto

the

next

step.

5)

To

check

the

manifold

gas

pressure

during

maximum

combustion,

press

and

hold

the

“

MAX

”

button

on

the

computer

board.

To

check

the

manifold

pressure

during

minimum

combustion,

press

and

hold

the

“

MIN

”

button

on

the

computer

board.

The

desired

pressures

are

listed

in

the

specification

table

at

the

beginning

of

this

manual.

6)

If

the

manifold

pressures

do

not

match

up

with

those

listed,

adjust

the

manifold

pressure

(see

the

following

procedure).

Figure

19