3D Systems, Inc.

17

p/n 76-D022 Rev. A

ProX

®

SLS 6100 TRANSFORMER REQUIREMENTS

If the facility does not have 208 VAC, 3-phase, 50/60 Hz, 10 kVA power, a customer-supplied step-up or step-down transformer is

required .

3D Systems stocks the following transformers:

DESCRIPTION

3D SYSTEMS PART NO .

Transformer, 230-250 Volt to 208VAC, 10kVA, 60Hz, 3PH

134005

Transformer, 460-500 Volt to 208VAC, 10kVA, 60Hz, 3PH

134006

Transformer, 385-415 Volt to 208VAC, 10kVA, 50Hz, 3PH (EU Version)

75-0265

•

If you purchase a transformer from a supplier other than 3D Systems, specify a “wye-to-delta” primary-to-secondary config-

uration .

•

Connect the transformer secondary neutral to the transformer secondary ground .

Caution: Do not connect the transformer secondary neutral to the printer ground.

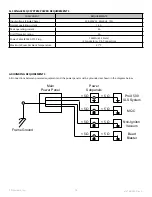

Refer to the ProX

®

SLS 6100 3D Printer Facility Requirements Poster and SLS Single MQC System Facility Requirements Poster

for visual layouts of the electrical connections .

NOTE: Please contact your local electrician to verify that your facility meets/has met its required local electrical

code .

NOTE: The ProX® SLS 6100 is designed to be connected to primary AC power directly from the facility’s power

circuit to the machine’s input power line filter. This task must be performed by a qualified electrician. The

facility’s power circuit must have a 50A branch protective circuit breaker or fused disconnect with lockout/

tagout capabilities .

ProX

®

SLS 6100 PROCESS STATION POWER REQUIREMENTS

COMPONENT

REQUIREMENTS

Process station input voltage

208 VAC, 10kVA, 50/60 Hz, 3PH

Normal operating current

10 to 21 A

Peak operating current

25 A

On/Off fuse rating

35 A

Power cable (for 3-phase power)

(3 Delta Cond P .E . connection)

Wire size according to local electrical code . Cable drop from ceiling over rear-left side of

process station

Power cable circuit breaker wiring

phase 1 to L1

phase 2 to L2

phase 3 to L3

•

The 3-phase power cable and cable gland (cord grip) are customer-supplied and installed . The cable feeds through the

access port on the top of the printer .

•

Connect the power cable ground wire to the ground bus bar in the printer’s power disconnect box .

•

Connect the printer to a dedicated power circuit .

9

ELECTRICAL REQUIREMENTS