3D Systems, Inc.

11

p/n 76-D022 Rev. A

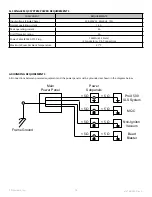

RECOMMENDED OPTIONAL EQUIPMENT

Your ProX

®

SLS 6100 System can optionally include the components listed below . These are described in the sections that

follow .

•

Room Area Oxygen Monitor

•

Bead Blaster

ROOM AREA OXYGEN MONITOR

Supplied by

: 3D Systems

•

Oxygen Room Monitor, 120V

•

Oxygen Room Monitor, 220V, Universal Plugs

Installed by

: 3D Systems

Source

: 3D Systems

For safety when working with nitrogen, 3D Systems recommends you install a room area oxygen monitor on the wall of your

ProX

®

SLS 6100 room .

Refer to the safety guidelines included in the ProX

®

SLS 6100 User Guide for information on safely working with nitrogen and

oxygen .

BEAD BLASTER

Supplied by

: 3D Systems

Installed by

: 3D Systems

If you plan to use DuraForm® SLS material, 3D Systems recommends

you install a pneumatic abrasive blast cabinet (bead blaster) in the

part finishing area separate from the ProX SLS 6100 3D Printer

process station room .

The Bead Blaster Station is a glass bead blaster which is very useful

for cleaning sintered DuraForm parts . It requires a 5 .5 bar (80 psi)

compressed air line and a 110 VAC/60 Hz power source (U .S . and Asia

Pacific version) or a 240 VAC/50 Hz power source (European version).

Caution: A anti-static mat is recommended during post-

processing to reduce the risk of shock .

4

RECOMMENDED OPIONAL EQUIPEMENT