©2022, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection.

7

Pallet stacking and destacking should be carried out by two people. The package with the

device should be lifted or moved using special handles.

Electromagnetic Compatibility (EMC)

The Zortrax printer complies with Part 15 of the FCC rules. Its operation is subject to the

following two conditions: this device may not cause harmful interference, and this device must

accept any interference received, including interference that may cause undesired operation.

The printer generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the following User Guide, may cause harmful interference to radio

communications. Operation of this device in a residential area is likely to cause harmful

interference, in which case the user will be required to eliminate the interference at his own

expense.

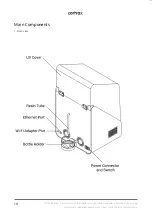

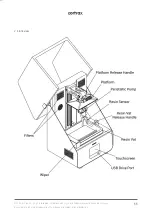

Learn More About the Zortrax Inkspire 2

The Zortrax Inkspire 2 is a 3D printer which, together with Z-SUITE, dedicated resins, and post-

processing devices — Zortrax Cleaning Station and Zortrax Curing Station, constitutes the

whole 3D printing ecosystem. The printer makes it possible to turn digital, three-dimensional

projects into reality using the UV LCD technology which relies on curing liquid photopolymer

layer after layer. The UV LCD technology involves projecting an image of a layer on the

transparent underside of the vat with liquid resin and curing the layer using backlight from an

integrated LED panel. After each layer is cured, the panel pauses to operate. During the pause,

the layer solidifies and the platform rises and lowers itself so the resin is equally distributed

in the vat. The printer is equipped with an LCD screen which is responsible for projecting

successive layers and masking the UV light. Thanks to that, the resin that is outside the image

of a layer is not cured and can be used to print the rest of the model. The printer allows users to

print multiple parts at the same time without affecting the accuracy and printing speed. Once

the printing process is finished, the model has to be post-processed in two steps. The first step

involves cleaning the print from residues of uncured resin in a liquid detergent, whereas the

second step involves additional UV curing so that the object acquires its intended properties.

The Zortrax Inkspire 2 can be used for creating prototypes and concept models in engineering,

as well as for creative applications, such as figurines and gadgets.