©2022, Zortrax S.A. All rights reserved. All trade names, logos and trademarks mentioned in the following

document are registered trademarks of Zortrax and are subject to legal protection.

12

Zortrax 3D Printing Technology Glossary

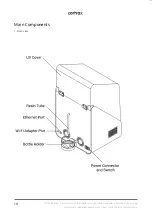

BOTTLE HOLDER

the component placed at the back of the printer which supports the resin level

management system and is an additional safety feature against overflow or shortage of

the resin. Thanks to the sensor installed in the holder, the amount of resin left in the

bottle is constantly measured. The holder has been designed to accommodate bottles

with different geometries.

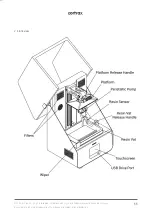

AIR FILTERS

the filters which absorb unpleasant smells from the air that passes through the printing

chamber. They are placed on the left- and right-hand side of the Z axis. In order to ensure

proper filtration during the printing process, the filters should be replaced every 3-4

months, or once they become considerably dirty, e.g. with liquid resin.

FIRMWARE

the software programmed into Zortrax printers, which controls and monitors all the data

in the device. It also gives the possibility to enable/disable the printer’s functions.

FEP FILM

the transparent foil which is installed in the rack attached to the resin vat. It creates a clean

way for the UV light to quickly and precisely cure liquid resin during the whole printing

process. The FEP film requires replacement once it becomes stretched or deformed.

LCD SCREEN

the flat-panel display essential for 3D printing in the UV LCD technology. It is responsible

for projecting images of layers on the underside of the resin vat during the whole printing

process. It also masks the UV light so that the resin that is outside the image of a layer is

not cured and can be used to print the rest of the model.

PERISTALTIC PUMP

A component which supports the resin management system and can automatically

transfer liquid resin from the bottle to the vat before the printing process or whenever it

is necessary. The pump also transfers the resin from the vat back to the bottle when users

want to change the resin type or empty the vat. To pump the resin out, use the plastic

spatula and scoop the liquid up towards the pump tube in the corner of the vat. Next, use

the options from the menu to pump the resin out.