10. Appendix 1

Content

No.

Name

M-055

Cyclic sewing pattern open error

Pattern file has mistake

M-056

Open file failed

Open file failed

M-057

Clear all customized parameters

Are You Sure

?

Yes

:

enter No

:

X

M-058

Over set range

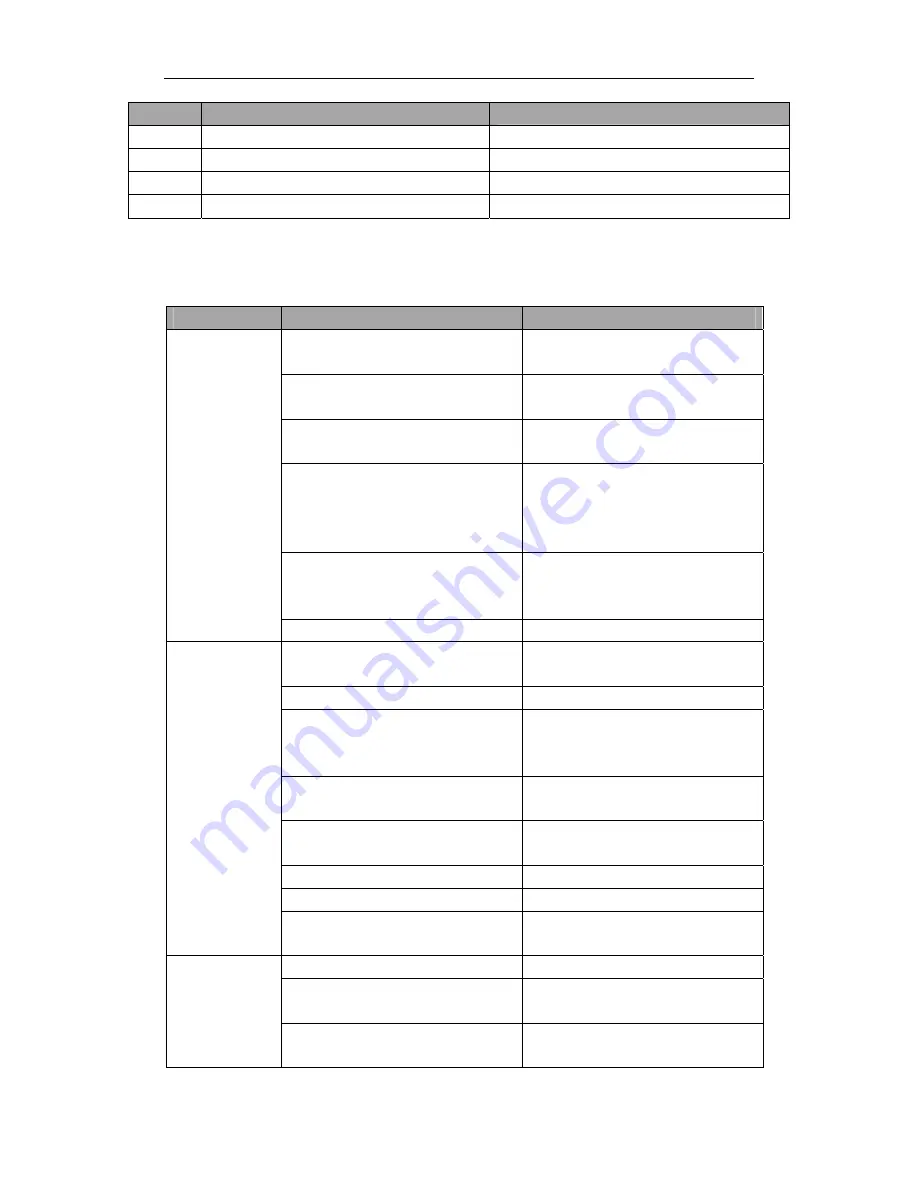

10-2. Malfunctions Settlement

Malfunction

Reasons

Solutions

Thread-tension is so high.

Adjust the thread-tension to proper

level

The

needle

is

not

properly

installed. Install the needle in the right

direction

Compared to needle, the thread is so

thick.

Select the thread fitting to the needle

The needle doesn’t match to the bend

needle.

Adjust the pitch between the needle

land bend needle, as well as the

height of needle rod, bend needle and

yarn divider.

There is damage or rags on needle,

bend needle, yarn divider, winding

plate or thread rail.

Polish or replace the rough parts.

Thread-breakage

Threading method is wrong.

Thread correctly.

The upper thread tension is too large

or too small.

Adjust the upper thread tension to a

proper level

The needle tip is broken or crooked.

Replace for a new needle

The interval between needle and bend

needle tip is incorrect.

Adjust the interval between the

needle and bend needle tip to a

proper level.

The needle, bend needle and yarn

divider don’t match to each other.

Adjust the relationships among these

three.

The needle and needle stand are not

adjusted properly.

Properly adjust the needle stand.

The bend needle tip is blunt.

Polish it or replace it.

The needle is not properly installed.

Install the needle in right direction.

Needle-jumping

The

needle

is

too

thin.

Select needles fit the sewing

conditions

The needle is crooked

Replace a new needle

The needle, bend needle and yarn

divider don’t match to each other

Adjust the relationships among these

three.

Needle-breakage

The needle and needle stand are not

adjusted properly.

Properly adjust the needle stand.

92

Summary of Contents for ZJ5820

Page 1: ......

Page 2: ......

Page 3: ......

Page 4: ......

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ...7 ...

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ...1 5 ...

Page 25: ...1 6 ...

Page 26: ......

Page 27: ...1 8 ...

Page 67: ...5 8 ...

Page 68: ...9 ...

Page 69: ...6 0 ...

Page 70: ...6 1 ...

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ...6 6 ...

Page 76: ...6 7 ...

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ...7 5 ...

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ...8 2 ...

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 108: ...10 Appendix 1 11 Appendix 2 11 1 Eyelet Buttonhole Machine System Diagram 99 ...