801910 v3.05 09.20 HT BCS Commercial Instructions

Page 9 of 32

Before Installation

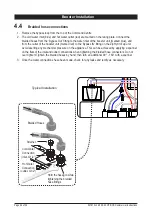

Before installing, ensure that the following have been provided at the installation site:

•

Review all the technical specifications.

•

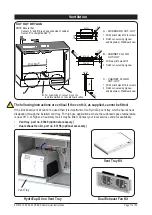

Ensure the underbench can support the product weight when full of water (allow an extra 4-5kg when

full).

•

Sufficient space in the cupboard to install the Command Centre in accordance with these Installation

Instructions. Refer to technical specification for dimensions. Make allowance for a booster heater and

/ or water softener if required. Refer to sections 4 and 5 for installation instructions.

•

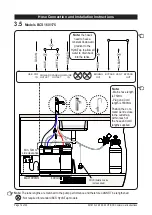

For Zip HydroTap 160/125 &160/175 models, a 220-240V AC, 10A power outlet will be required. For

Zip HydroTap 240/175 models, two 220-240V AC, 10A power outlets will be required (one power

outlet for the Zip HydroTap and the other for the Booster heater).

Note

Note

: Check all cable and hose lengths against inlet /outlet positions before proceeding

(See section 3 for general layout).

•

A potable water supply connection with isolating valve inside the cupboard within reach of the braided

hoses and positioned so that the connection point and the stop cock will not be obstructed when the

Command Centre is installed.

•

For the mains pressure All-in-One tap, an external hot and cold water supply will be required.

•

If an external filtration or water softening device is required, then it is important to allow extra space

for these items.

•

A cold water supply with a minimum working pressure of 300kPa and a maximum working pressure

of 700kPa connected via an isolation valve.

•

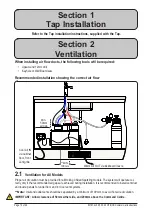

The fitting of an air flow duct, attached to the side of the unit, requires a rectangular cut size of

284mm x 45mm, to provide adequate warm air displacement. See Section 2.

•

The appliance must be placed with its base in a horizontal position.

IMPORTANT!

Do not proceed with the installation if these requirements are not met.

!

Special Tools Required:

In addition to normal tools, the following will be required:

For the standard and Mixer taps:

•

35mm diameter sheet metal hole punch for sink tops (not supplied)

•

35mm diameter hole saw for timber bench tops (not supplied)

•

Nut runner tube spanner (supplied) for fixing tap assembly.

For the All-In-One tap:

•

50mm diameter sheet metal hole punch for sink tops (not supplied)

•

50mm diameter hole saw for timber bench tops (not supplied)

•

Nut runner tube spanner (supplied) for fixing tap assembly.