Spectrum Z™510 3D Printer Hardware Manual

Introduction

www.3dpuser.com

4

10/2/07

All Rights Reserved

3 Introduction

3.1 How It Works

The 3D Printer System is based on the Massachusetts Institute of Technology's patented 3DP™ (3D Print-

ing) technology.

The software first converts a three-dimensional design built using 3D CAD into cross sections or slices that

are between 0.0035" - 0.004" (0.0875 - 0.1 mm) thick.

The printer then prints these cross-sections one after another from the bottom of the part to the top.

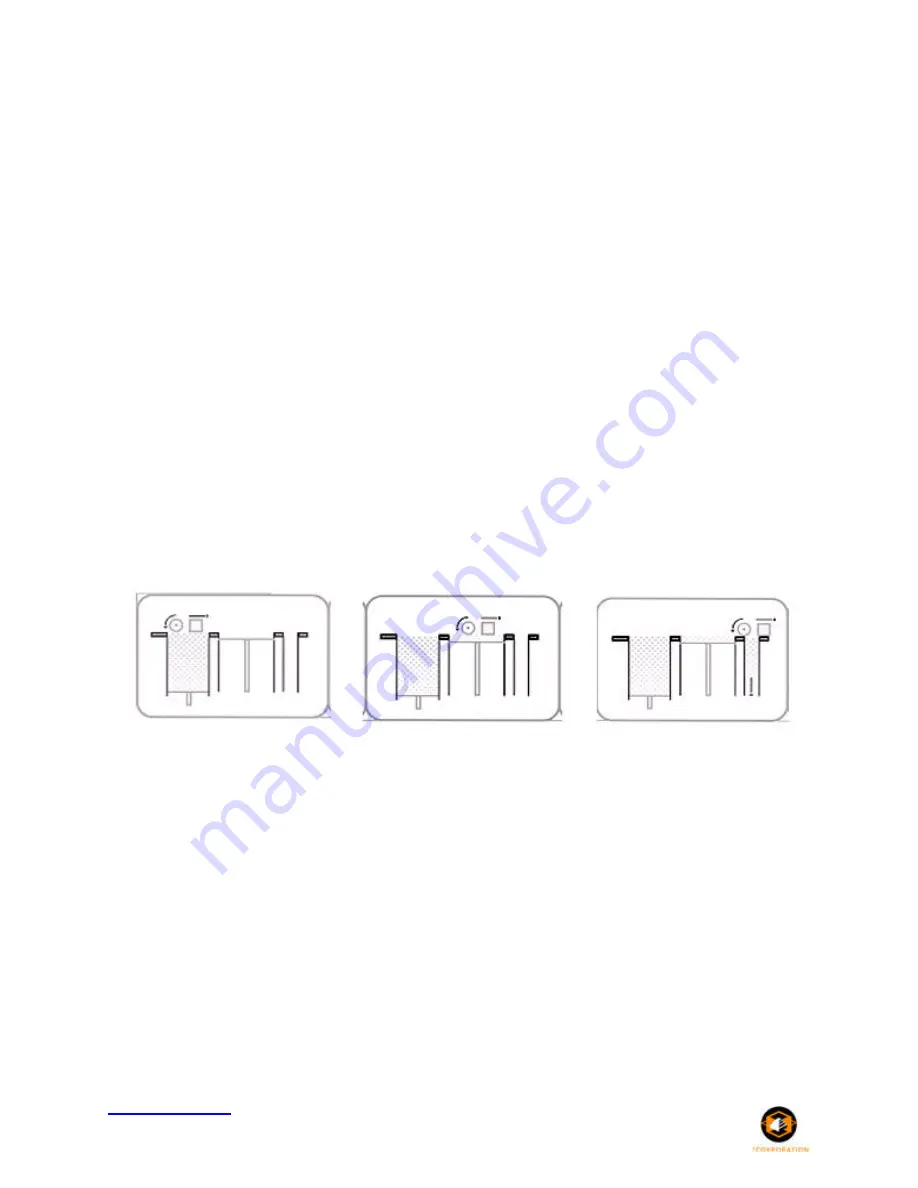

Inside the printer there are two pistons (see diagram below). The feed piston is represented in the dia-

grams below. Starting on the left the piston is shown in the 'down' position filled with powder. The build pis-

ton is the piston on the right, and is shown below in the 'up' position. Also represented in the diagrams are

the roller (drawn as a circle) and the print assembly (drawn as a square.) On the printer, the roller and the

print assembly are mounted together on the gantry which moves horizontally across the build area.

To begin the 3D printing process, the printer first spreads a layer of powder in the same thickness as the

cross-section to be printed. The print heads then apply a binder solution to the powder causing the powder

particles to bind to one another and to the printed cross-section one level below. The feed piston comes

up one layer and the build piston drops one layer. The printer then spreads a new layer of powder and

repeats the process, and in a short time the entire part is printed.

Step 1: As the gantry

traverses left to right, the

roller collects powder.

Step 2: The roller spreads a

thin layer of powder over the

build piston.

Step 3: The roller discharges

excess powder down the

powder overflow chute.