28

440 01 2020 01

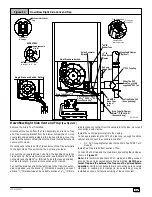

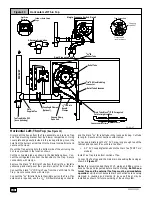

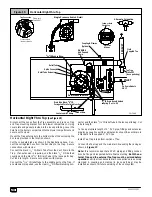

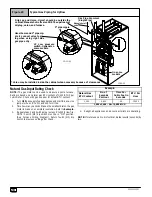

Manual shut- off

valve

Use elbows and 3

²²²²

pipe nip-

ple to connect valve to pip-

ing when using right side

gas pipe entry.

* Union may be installed inside the cabinet when necessary because of clearances.

Figure 29

Typical Gas Piping for Upflow

Drip Leg and Union, Union* should be outside the

cabinet. Manual shut--off valve MUST be upstream of

dripleg, union, and furnace.

LP Low pressure

switch. Optional on

some models.

Gas Pipe Grommet

(Single Pipe)

3

²²²²

pipe nipple

25--23--84

On some

models

25--24--22

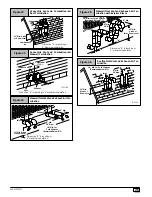

Natural Gas Input Rating Check

NOTE:

The gas meter can be used to measure input to furnace.

Rating is based on a natural gas BTU content of 1,000 BTU’s per

cubic meter. Check with gas supplier for actual BTU content.

1. Turn

OFF

gas supply to all appliances and start furnace. Use

jumper wire on R to W1 and W2 for Hi fire.

2. Time how many seconds it takes the smallest dial on the gas

meter to make one complete revolution. Refer to

Example

.

3. Repeat steps 1 and 2 with jumper wire on R to W2 for low fire.

NOTE: Fourth (4th) dip switch must be in “ON” position.

(See Furnace Wiring Diagram). Return fourth (4th) dip

switch to previous setting after check.

Example

Natural Gas

BTU Content

No. of

Seconds

Per Hour

Time Per

Cubic Foot in

Seconds

BTU Per

Hour

1,000

3,600

48

75,000

1,000 x 3,600

¸

48 = 75,000 BTUH

4. Relight all appliances and ensure all pilots are operating.

NOTE:

If meter uses a 2 cubic foot dial, divide results (seconds) by

two.

Summary of Contents for 9MPT050F12A

Page 46: ...46 440 01 2020 01...