7

440 01 2020 01

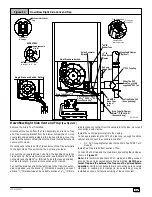

Horizontal Furnace Installation

This furnace can be installed horizontally in an attic, basement,

crawl space, alcove, or suspended from a ceiling in a basement or

utility room (See

Figure 4

).

Do not

install furnace on its back or in

the reverse airflow positions as safety control operation will be ad-

versely affected.

Inlet Pipe

(not used on Single Pipe model)

Typical Horizontal Installation

Figure 4

Vent

Pipe

Condensate

Trap

NOTE: 5

²

bottom clearance required for condensate trap.

25--23--34

If the furnace is to be suspended from the floor joists in a crawl

space or the rafters in an attic, it is necessary to use steel pipe

straps or an angle iron frame to rigidly attach the furnace to prevent

movement. These straps should be attached to the furnace with

sheet metal screws and to the rafters or joists with bolts. The pre-

ferred method is to use an angle iron frame bolted to the rafters or

joists. (Take caution to allow door panels to be removed for mainte-

nance)

If the furnace is to be installed in a crawl space, consult local codes.

A suitable concrete pad or blocks are recommended for crawl

space installation on the ground.

NOTE: 6

²

bottom clearance required for condensate trap.

Thirty (30) inches between the front of the furnace and adjacent

construction or other appliances

MUST

be maintained for service

clearance.

Keep all insulating materials clear from louvered door. Insulating

materials may be combustible.

The horizontal furnaces may be installed directly on combustible

wood flooring or supports as long as all required furnace clear-

ances are met. See

Figure 4.

This furnace

MUST NOT

be installed directly on carpeting or tile or

other combustible material other than wood flooring or supports.

For horizontal installation over a finished living space. A field fabri-

cated auxiliary drain pan with drain pipe is required to prevent dam-

age by overflow due to blocked condensate drain.

3. Combustion & Ventilation Air

For Single Pipe Installation

CARBON MONOXIDE POISONING HAZARD

Failure to provide adequate combustion and ventilation

air can result in death and/or personal injury.

Use methods described here to provide combustion and

ventilation air.

!

Furnaces require ventilation openings to provide sufficient air for

proper combustion and ventilation of flue gases. All duct or open-

ings for supplying combustion and ventilation air must comply with

National Fuel Gas Code, NFPA54/ANSI Z223.1, 2002 (or current

edition) and applicable provisions of local building codes.

This furnace can NOT be common vented or connected to any type

B, BW or L vent or vent connector, nor to any portion of a factory--

built or masonry chimney. If this furnace is replacing a previously

common-vented furnace, it may be necessary to resize the existing

vent and chimney to prevent oversizing problems for the other re-

maining appliance(s). See

“Venting and Combustion Air Check”

in

this section

.

This furnace MUST be vented to the outside.

Air Openings and Connecting Ducts

1. Total input rating for all non direct vent gas appliances

MUST

be considered when determining free area of openings.

2. Connect ducts or openings directly to outside.

3. When screens are used to cover openings, they

MUST

be

no less than

1

/

4

²

mesh.

4. The minimum dimension of rectangular air ducts

MUST

NOT

be less than 3

²

.

5. When sizing grille or louver, use the free area of opening. If

free area is

NOT

stamped or marked on grill or louver, as-

sume a 20% free area for wood and 60% for metal.

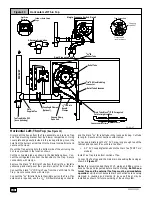

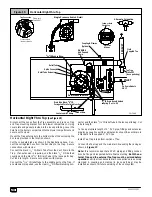

Confined Space Installation

NOTE

: A confined space is defined as an area with less than 50

cubic feet per 1,000 BTUH input rating for all gas appliances

installed in the area.

Requirements

1. Provide confined space with sufficient air for proper com-

bustion and ventilation of flue gases using horizontal orverti-

cal ducts or openings.

2.

Figure 5

illustrate how to provide combustion and ventila-

tion air. A minimum of two permanent openings, one inlet

and one outlet, are required.

Summary of Contents for 9MPT050F12A

Page 46: ...46 440 01 2020 01...