30

440 01 2020 01

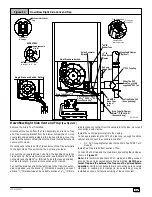

6. Electrical Wiring

Electrical shock hazard.

Turn OFF electrical power at fuse box or service

panel before making any electrical connections

and ensure a proper ground connection is made

before connecting line voltage.

Failure to do so can result in death, personal injury

and/or property damage.

!

Power Supply Wiring

The furnace

MUST

be electrically wired and grounded in accor-

dance with local codes, or in the absence of local codes with the

latest edition of The National Electric Code, ANSI NFPA 70 and/or

The Canadian Electric Code CSA C22.1.

Field wiring connections must be made inside the furnace connec-

tion box. A suitable strain relief should be used at the point the

wires exit the furnace casing.

Copper conductors must be used

. Line voltage wires should be

sized for the input amps stated on the rating plate. Furnace should

be connected to its own separate circuit.

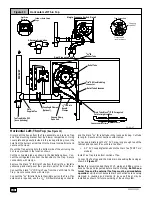

Thermostat

The 2--stage furnace control will operate with either a single stage

or a two stage heating thermostat and will provide 2--stage heating

operation. For single stage thermostat installations, the

R

and

W

wires from the thermostat connect to the

R

and

W1

connections on

the furnace control.

Note:

The fourth (4th) DIP switch must be in

the off position, failure to change DIP switch will result in Lo Fire

ONLY operation. (See furnace wiring digram) See “

Furnace Wiring

Diagram

” for switch settings. Failure to set DIP switch will result in

Lo fire operation ONLY with single stage thermostat. During opera-

tion, the furnace will operate on low fire for 12 minutesIf the heat

request exists for more than 12 minutes. If the heat request exists

for more that 12 minutes, the furnace will automatically shift to the

high fire mode for the remaining duration of the heating cycle. For

two stage thermostat installations, the

R, W1

and

W2

wires from

the thermostat connect to the

R, W1

and

W2

connections on the

furnace control. During operation, the furnace will shift from low fire

to high fire as requested by the thermostat. The thermostat heat

anticipators should be adjusted to a .10 setting for both types of

thermostats.

Low voltage connections to furnace must be made on terminal

board to fan control.

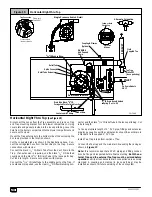

Optional Equipment

All wiring from furnace to optional equipment

MUST

conform to lo-

cal codes or, in the absence of local codes with the latest edition of

The National Electric Code, ANSI NFPA 70 and/or The Canadian

Electric Code CSA C22.1. Install wiring in accordance with

manufacturer’s instructions. The wiring

MUST

have a minimum

temperature rating of 105

°

C. codes or, in the absence of local

codes, the applicable national codes. Install wiring in accordance

with manufacturer’s instructions.

Humidifier/Electronic Air Cleaner

The furnace is wired for humidifier and/or electronic air cleaner

connection.

CAUTION

Do NOT exceed 115V/0.8 amp. maximum current load for both

the EAC terminal and the HUM terminal combined.

NOTE:

The humidifier will be powered when the furnace is fired

and the circulating air blower comes on. The electronic air cleaner

will be powered anytime the air circulating blower is energized.

However, the electronic air cleaner is

NOT

energized during con-

tinuous fan operation controlled by the electronic fan control.

Fan Control

The fan control is preset at the factory with a fixed blower

ON

delay

of 30 seconds in the heating mode. The blower

OFF

timing is pre-

set at 140 seconds. If desired, the fan

OFF

delay can be reset to

obtain the longest delay times while still maintaining comfort levels.

See “Furnace Wiring Diagram” .

W2

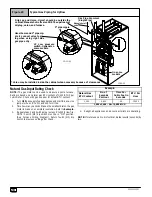

Figure 31

Electrical Connections

NOTE: Junction Box can be mounted to either the left or right side.

25--23--42a

W2

W2

NOTE: 115 VAC/60Hz/single--phase

Operating voltage range*: 127 max, 104 min.

* Permissible limits of voltage at which unit will operate satisfactorily

Dehumidification -- Variable Speed ONLY (*9MPV)

The fan control is wired for 24 VAC normally open (N/O) dehumidis-

tat connection. Connect dehumidistat to the

R

terminal and the

1

/

4

²

male quick connect Y2 terminal on the fan control (See

Figure 32

and “Furnace Wiring Diagram”). A 20% reduction of cooling airflow

will occur when the Y2 dehumidistat terminal is energized during a

call for cooling from the thermostat.

Control Center Fuse

The 24V circuit contains a 5--amp, automotive--type fuse located

on fan timer board. (See

Figure 32

) Any electrical shorts of 24V

wiring during installation, service, or maintenance may cause fuse

to blow. If fuse replacement is required, use only a fuse of identical

size (5 amp.)

Summary of Contents for 9MPT050F12A

Page 46: ...46 440 01 2020 01...