33

440 01 2020 01

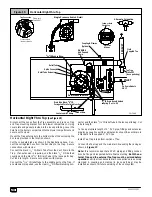

Downflow Furnace Installation

Non- Combustible Floor Installation

Fabricate a plenum to the dimensions given in

Figure 3

, for the fur-

nace outlet. Plenum should be flanged, approximately

3

/

4

²

for sup-

port.

Note: The three(3) screws in the top panel of the furnace next to the

duct flange

MUST

be removed to provide serviceability of the pri-

mary heat exchangers in the downflow installation

1. Position plenum through the floor and set the furnace over

the opening in the floor. If necessary, grout around the base

to seal air leaks between the base and the floor.

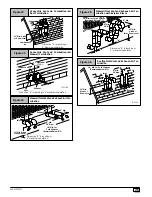

Combustible Floor Installation

FIRE HAZARD.

Failure to install unit on noncombustible subbase can

result in death, personal injury and/or property damage.

Place furnace on noncombustible subbase on downflow

applications, unless installing on non--combustible

flooring.

!

Subbase for Combustible Floor

NOTE:

The three(3) screws in the top panel of the furnace next to

the duct flange

MUST

be removed to provide serviceability of the

primary heat exchangers in the downflow installation

Note: When using the subbase for combustible floors, the dis-

charge air duct flanges on the furnace MUST be broken down to

provide proper fit up to the subbase. Use duct pliers to bend the

duct flanges flat onto the furnace casing. DO NOT bend the duct

flanges inward (toward the heat exchangers) as air flow restrictions

may occur.

The Subbase for Combustible Floors

MUST

be used when a down-

flow furnace is set on a combustible floor, even when the furnace is

installed on a coil box.

1. Cut the opening in the floor according to

Table 7

. The hole in

the floor must be cut to the dimensions listed in

Table 7

since the base is equipped with locating tabs that center the

base over the opening.

The opening in the base is 1

1

/

4

²

shorter and 1

1

/

8

²

narrower than the

recommended size of the opening in the floor. This is done to main-

tain clearance between the floor and the plenum.

2. Fabricate the plenum to the dimensions given in

Table 7

.

Note that the dimensions given are outside dimensions.

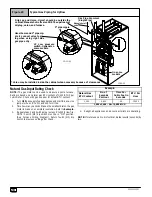

Table 7

Subbases for Combustible Floors Dimensions

Subbase for Combustible

Floors Part Number

Subbase for Combustible

Floor Dimensions

Opening In Floor

Opening In Base

For Plenum

Typical Plenum

Dimensions

Floors Part Number

H*

J*

K**

L

M

N

P

R

S

T

Furnace Subbase

NAHH001SB

15

11

/

16

28

3

/

4

14

9

/

16

16

16

1

/

4

14

5

/

8

15

13

1

/

2

15

13

1

/

2

NAHH002SB

19

5

/

16

28

3

/

4

18

3

/

16

16

16

1

/

4

18

1

/

4

15

17

1

/

8

15

17

1

/

8

NAHH003SB

22

5

/

16

28

3

/

4

21

13

/

16

16

16

1

/

4

21

7

/

8

15

19

3

/

4

15

19

3

/

4

NAHH010SB

24

11

/

16

28

3

/

4

23

9

/

16

16

16

1

/

4

23

5

/

8

15

22

1

/

2

15

22

1

/

2

Subbase for Coil Cabinets

NAHH004SB

15

11

/

16

20

9

/

16

14

9

/

16

16

1

/

4

16

1

/

4

14

5

/

8

15

13

1

/

2

15

13

1

/

2

NAHH005SB

19

5

/

16

20

9

/

16

18

3

/

16

16

1

/

4

16

1

/

4

18

1

/

4

15

17

1

/

8

15

17

1

/

8

NAHH006SB

23

20

9

/

16

21

13

/

16

16

1

/

4

16

1

/

4

21

7

/

8

15

19

3

/

4

15

19

3

/

4

NAHH009SB

24

3

/

4

20

9

/

16

23

9

/

16

16

1

/

16

16

1

/

4

23

5

/

8

15

22

1

/

2

15

22

1

/

2

*

Outside Dimension

**

Base Spacer Side To Side

3. Set the base over the opening in the floor, centering it over

the opening. Fasten the base to the floor with screws or

nails. See

Figure 37, Figure 38

and

Figure 39

.

4. Drop the plenum through the opening in the base. The

flange of the plenum should rest on top of the subbase.

5. Position furnace or coil cabinet and furnace on subbase so it

aligns between the locating tabs.

T

S

H

J

1”

2”

N

M

R

P

L

2”

25--20--46

Plenum

Combustible

Floor Base

Furnace Subbase

Figure 37

A

A = 4

1

/

4

” Minimum

clearance from back of

hole to wall or other

obstruction.

Hole in

Floor

K

Summary of Contents for 9MPT050F12A

Page 46: ...46 440 01 2020 01...