12

440 01 2020 01

Vent Termination Clearances

(United States Only)

Figure 7

In Canada See Canadian Fuel Gas Code

Direct Vent

Terminal

50,000 Btuh

or less

Other Than

Direct Vent

Terminal

Direct Vent Terminal

More Than 50,000 Btuh

Other Than

Direct Vent

Terminal

Other Than

Direct Vent

Terminal

Forced Air

Inlet

10--11--36

9

²

12

²

12

²

12

²

12

²

12

²

10

¢

3

¢

4

¢

4

¢

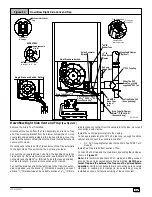

Condensate Drain Trap

This furnace removes both sensible and latent heat from the prod-

ucts of combustion. Removal of the latent heat results in con-

densation of the water vapor. The condensate is removed from the

furnace through the drains in the plastic transition and the vent fit-

ting. The drains connect to the factory installed internally mounted

condensate drain trap on the left or right side of the furnace.

The startup of a new furnace will involve a cycle or two of the fur-

nace to properly prime the condensate trap with water. Until the

trap is fully primed, some condensate will be pulled into the com-

bustion blower. The furnace may cycle on the pressure switch con-

nected to the plastic transition box due to condensate buildup.

After the trap is primed, the condensate will start draining from the

furnace. The combustion blower will clear out any remaining con-

densate in the blower housing through the vent fitting downstream

of the blower. Note that the condensate trap can also be primed by

pouring water into the

1

/

2

²

drain hose. Remove the

1

/

2

²

ID drain

hose from either the gutter or the white PVC Tee Trap. Using a fun-

nel pour eight (8) ounces of water into

1

/

2

²

ID drain hose.Water will

flow through the drain hose and into the condensate drain trap.

This will prime both the vent and the transition sides of the trap. Re-

connect the

1

/

2

²

ID drain hose to the original component, either the

gutter or the PVC Tee Trap.

The condensate drain trap supplied with the furnace MUST be

used. The drain connection on the condensate drain trap is sized

for

3

/

4

²

PVC or CPVC pipe, however alternate

1

/

2

²

CPVC (nominal

5

/

8

²

O.D.) or vinyl tubing with a minimum inner diameter (I.D.) of

5

/

8

²

may also be used, as allowed by local codes. Alternate drain

pipes and hoses may be used as allowed by local codes.

The drain line must maintain a

1

/

4

²

per foot downward slope toward

the drain.

1

/

4

²

per foot is recommended. Installation of an overflow

line is recommended when the

1

/

4

²

per foot slope to the conden-

sate drain cannot be maintained. See

Figure 1

for proper routing

and installation of the overflow.

DO NOT trap the drain line in any other location than at the conden-

sate drain trap supplied with the furnace.

FROZEN AND BURST WATER PIPE HAZARD.

If a condensate pump is installed, a plugged condensate

drain or a failed pump may cause the furnace to shut

down. Do not leave the home unattended during freezing

weather without turning off water supply and draining

water pipes or otherwise protecting against the risk of

frozen pipes.

Failure to do so may result in burst water pipes, serious

property damage and/or personal injury.

!

If possible DO NOT route the drain line where it may freeze. The

drain line must terminate at an inside drain to prevent freezing of

the condensate and possible property damage.

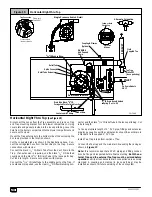

1. A condensate sump pump

MUST

be used if required by local

codes, or if no indoor floor drain is available. The conden-

sate pump must be approved for use with acidic conden-

sate.

2. A plugged condensate drain line or a failed condensate

pump will allow condensate to spill. If the furnace is installed

where a condensate spill could cause damage, it is recom-

mended that an auxiliary safety switch be installed to pre-

vent operation of the equipment in the event of pump failure

or plugged drain line. If used, an auxiliary safety switch

should be installed in the R circuit (low voltage)

ONLY

.

3. If the auxiliary switch in the condensate pump is used, the

furnace may shut down due to a blocked condensate line or

failed pump. To prevent frozen water pipes see the “Frozen

Water Pipe Hazard” section on Page 4 of this manual.

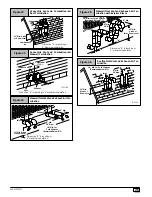

Condensate Drain Trap Freeze Protection

Special precautions

MUST

be made if installing furnace in an area

which may drop below freezing. This can cause improper opera-

tion or damage to the equipment. If the the furnace environment

has the potential of freezing, the drain trap and drain line must be

protected. Use 3 to 6 watt per foot at 115 volt, 40

°

F self--regulating

shielded and waterproof heat tape. Wrap the drain trap and drain

line with the heat tape and secure with the ties. Follow the heat tape

manufacturer’s recommendations.

Summary of Contents for 9MPT050F12A

Page 46: ...46 440 01 2020 01...