035-17480-000 Rev. A (800)

18

Unitary Products Group

METHOD THREE: TWO PIPE SYSTEM USING

COMBUSTION AIR FROM A VENTILATED ATTIC

SPACE

This type installation requires two properly sized pipes. One

brings combustion air from a properly ventilated attic space

and a second pipe from the furnace vent connection (top right

of unit) exits to the outdoors.

COMBUSTION AIR INTAKE

Refer to Table 3 on page 12, for intake pipe sizing, allowable

length and elbow usage. Follow all notes, procedures and

required materials in the Two-Pipe Sealed Combustion sec-

tion (Method 1) when installing the combustion air pipe within

the unit and into the ventilated attic space.

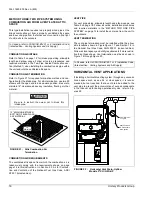

COMBUSTION AIR TERMINATION

Refer to Figure 21 for required termination method and con-

figuration for the intake pipe. For attic termination, use two 90

elbows with the open end in a downward position. Be sure to

maintain 12" clearance above any insulation, flooring or other

material.

COMBUSTION AIR REQUIREMENTS

The ventilated attic space from which the combustion air is

taken must comply with the requirements shown on page

page 14 in this instruction or in Section 5.3, Air for Combus-

tion and Ventilation of the National Fuel Gas Code, ANSI

Z223.1 (latest edition).

VENT PIPE

For vent pipe sizing, allowable length and elbow usage, see

Table 5 on page 16. Follow all notes, installation procedures

and required materials in the “METHOD TWO ONE PIPE

SYSTEM”, on page 14 to install the vent pipe from the unit to

the outdoors.

VENT TERMINATION

The vent pipe termination must be installed within the allow-

able locations shown in FigureFigure 17 and Section 7.8 in

the National Fuel Gas Code, ANSI Z223.1 (current edition).

Follow all local agency and utility requirements if more restric-

tive than those shown. Vent termination must be as shown in

Figure 18 through Figure 20.

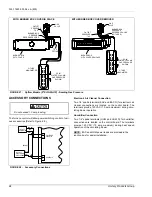

HORIZONTAL VENT APPLICATIONS

If installing a horizontal venting system through any uncondi-

tioned space such as an attic or crawl space, it is recom-

mended, but not required, that a vent drain be added to the

vent pipe to prevent the accumulation of excess condensate

in the inducer motor during operational cycles, refer to Fig-

ures 22.

In Canada, refer to CAN/CGA-B149.1 or .2 Installation Code

(latest edition - Venting Systems and Air Supply)

FIGURE 21 :

Attic Combustion Air

Termination

Be sure to instruct the owner not to block this

intake pipe.

1 2 " M I N I M U M B E T W E E N

B O T T O M O F E L B O W A N D

A N Y M A T E R I A L

1 2 "

M I N I M U M

In Canada, refer to CAN/CGA-B149.1 or .2 Installation Code

(latest edition - Venting Systems and Air Supply)

FIGURE 22 :

Horizontal Vent Drain -Upflow

Models P*XU / G9D-UP

NEUTRALS

EAC

COOL

HEAT

HUM

PARK

PARK

L1

XFMR

Y

W

R

G

C

3.00" Minimum

Loop Dia.

Attach This End

To Condensate

Drain System