035-17480-000 Rev. A (800)

Unitary Products Group

13

VENTING MULTIPLE UNITS

Each unit must have its own intake/vent piping and termina-

tion. Do not use common pipes for combustion air or venting.

The vent terminals must be located as shown in Figure 14

and Figure 15.

PIPING ASSEMBLY

The final assembly procedure for the vent/combustion air pip-

ing is as follows:

1.

Cut piping to the proper length, beginning at the furnace.

2.

Deburr the piping inside and outside.

3.

Chamfer the outer edges of the piping.

4.

Dry-fit the entire vent/combustion air piping assembly.

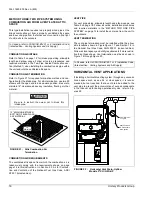

FIGURE 11 :

Horizontal Termination Raised Configura-

tion For Additional Clearance

FIGURE 12 :

Horizontal Termination Configuration With

Horizontal Extension

VENT

OVERHANG

COMBUSTION AIR

(ELBOW PARALLEL TO WALL)

12" SEPARATION BETWEEN

BOTTOM OF COMBUSTION AIR

AND BOTTOM OF VENT

MAINTAIN 12" CLEARANCE ABOVE

HIGHEST ANTICIPATED SNOW LEVEL

OR GRADE, WHICHEVER IS GREATER

12" MINIMUM

90°

VENT

OVERHANG

COMBUSTION AIR

12" SEPARATION BETWEEN

BOTTOM OF COMBUSTION AIR

AND BOTTOM OF VENT

MAINTAIN 12" CLEARANCE ABOVE

HIGHEST ANTICIPATED SNOW LEVEL

OR GRADE, WHICHEVER IS GREATER

12" MINIMUM

90°

18" MAXIMUM

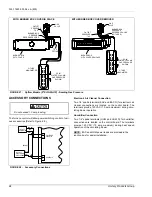

FIGURE 13 :

Vertical Termination

FIGURE 14 :

Double Sidewall Termination

FIGURE 15 :

Double Rooftop Termination

MAINTAIN 12" MINIMUM

CLEARANCE ABOVE HIGHEST

ANTICIPATED SNOW LEVEL.

MAXIMUM OF 24" ABOVE ROOF

COMBUSTION AIR

VENT

12" VERTICAL SEPARATION

BETWEEN COMBUSTION

AIR AND VENT

VENT

COMBUSTION AIR

2"

6"