035-17480-000 Rev. A (800)

28

Unitary Products Group

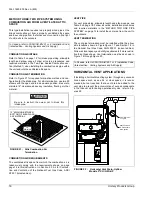

INTERMITTENT BLOWER - COOLING

On cooling/heating thermostats with fan switch, when the fan

switch is set in the auto position and the thermostat calls for

cooling, a circuit is completed between the R, Y and G termi-

nals.

The motor is energized through the cool fan terminal and

runs on the selected speed. The fan off setting is fixed at 60

seconds for SEER enhancement.

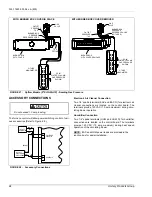

HEATING OPERATIONAL SEQUENCE

Two-Stage Thermostat

In a typical system, a call for first stage heat is initiated by

closing the W1 thermostat contacts. The inducer blower is

energized at high speed and the control waits for the low

pressure switch contacts to close. The inducer blower is

energized at low speed and the 120 VAC silicon carbide

igniter is powered.

At the end of the igniter warm-up time, the first stage of the

two-stage gas valve is energized (low fire). Flame must be

detected within 7 seconds. If flame is detected, the delay-to-

fan-on period begins. After the delay-to-fan-on period ends,

the circulator fan is energized at low heat speed and the air

cleaner and humidifier are energized.

A call for second stage heat (W1 and W2) after a call for first

stage heat will energize the inducer at high speed and ener-

gize the circulator at high heat speed. The second stage

pressure switch contacts will close and energize the second

stage gas valve (high fire).

If a call for second stage heat occurs at the same time as a

call for first stage heat, the second stage heat is energized as

above.

When the second stage of the thermostat is satisfied, the

inducer motor is reduced to low speed and the second stage

gas valve is de-energized upon opening of the second stage

pressure switch contacts. The circulator remains on high heat

speed for 30 seconds and then is reduced to low heat speed.

When the first stage of the thermostat is satisfied, the gas

valve is de-energized and the heat delay to fan off begins tim-

ing. The inducer will post-purge for an additional 5 seconds,

then the inducer and humidifier will de-energize. Upon com-

pletion of the heat delay-to-fan-off, the circulator and air

cleaner are de-energized. The control timing is graphically

shown in Figure 29 on page 27.

If flame is not detected during the trial-for-ignition period, the

gas valve is de-energized, the ignitor is turned off and the

50A51 control goes into the retry sequence.

The retry sequence provides a 120-second wait with inducer

inter-purge following an unsuccessful ignition attempt (flame

not detected). After this wait, the ignition sequence is

restarted with an additional 10 seconds of ignitor warm-up

time. Two retries will be attempted before the control goes

into system lockout.

If flame is detected, then lost, the 50A51 control will repeat

the initial ignition sequence. After 5 attempts to sustain flame,

the control will go into system lockout.

If flame is established for more than 10 seconds after ignition,

the 50A51 controller will clear the ignition attempt (or retry)

counter. If flame is lost after 10 seconds, it will restart the igni-

tion sequence. This can occur a maximum of 5 times before

system lockout.

During burner operation, a momentary loss of power of 50

milliseconds or longer will de-energize the main gas valve.

When power is restored, the gas valve will remain de-ener-

gized and a restart of the ignition sequence will begin imme-

diately.

A momentary loss of gas supply, flame blowout, or a shorted

or open condition in the flame probe circuit will be sensed

within 0.8 seconds. The gas valve will de-energize and the

control will restart the ignition sequence.

Recycles will begin and the burner will operate normally if the

gas supply returns, or the fault condition is corrected, before

the last ignition attempt. Otherwise, the control will go into

system lockout.

If the control has gone into system lockout, it may be possible

to reset the control by a momentary power interruption of one

second or longer. Refer to the diagnostics section of this

instruction for reset information.

Single-Stage Thermostat

If a single stage thermostat is used the unit will be controlled

as above with the following exception. On a call for heat the

unit will operate on low fire as detailed above. If the heating

requirements cause the cycle to exceed 10 minutes, the high

fire timer will energize the second stage heat. The second

stage operation will function as detailed above. The heating

cycle will be completed in high fire operation.

Hot Surface Ignition System

Do not attempt to light this furnace by hand (with a

match or any other means). There may be a

potential shock hazard from the components of the

hot surface ignition system. The furnace can only

be lit automatically by its hot surface ignition

system.