035-17480-000 Rev. A (800)

26

Unitary Products Group

FILTER PERFORMANCE

The airflow capacity data published in Table 8 represents

blower performance WITHOUT filters. To determine the

approximate blower performance of the system, apply the fil-

ter drop value for the filter being used or select an appropri-

ate value from the Table 8.

NOTE: The filter pressure drop values in Table 8 are typical

values for the type of filter listed and should only be used as a

guideline. Actual pressure drop ratings for each filter type

vary between filter manufacturer.

APPLYING FILTER PRESSURE DROP TO

DETERMINE SYSTEM AIRFLOW

To determine the approximate airflow of the unit with a filter in

place, follow the steps below:

1.

Select the filter type.

2.

Select the number of return air openings or calculate the

return opening size in square inches to determine the

proper filter pressure drop.

3.

Determine the External System Static Pressure (ESP)

without the filter.

4.

Select a filter pressure drop from the table based upon

the number of return air openings or return air opening

size and add to the ESP from Step 3 to determine the

total system static.

5.

If total system static matches a ESP value in the airflow

table (i.e. 0.20, 0.60, etc,) the system airflow corre-

sponds to the intersection of the ESP column and Model/

Blower Speed row.

6.

If the total system static falls between ESP values in the

table (i.e. 0.58, 0.75, etc.), the static pressure may be

rounded to the nearest value in the table determining the

airflow using Step 5 or calculate the airflow by using the

following example.

Example: For a 130,000 Btuh furnace with 2 return openings

and operating on high speed blower, it is found that total sys-

tem static is 0.58" w.c. To determine the system airflow, com-

plete the following steps:

1.

Obtain the airflow values at 0.50" & 0.60" ESP.

Airflow @ 0.50": 2125 CFM

Airflow @ 0.60": 2035 CFM

2.

Subtract the airflow @ 0.50" from the airflow @ 0.60" to

obtain airflow difference.

2035 - 2125 = -90 CFM

3.

Subtract the total system static from 0.50" and divide this

difference by the difference in ESP values in the table,

0.60" - 0.50", to obtain a percentage.

(0.58 - 0.50) / (0.60 - 0.50) = 0.8

4.

Multiply percentage by airflow difference to obtain airflow

reduction.

(0.8) x (-90) = -72

5.

Subract airflow reduction value to airflow @ 0.50" to

obtain actual airflow @ 0.58" ESP.

2125 - 72 = 2053

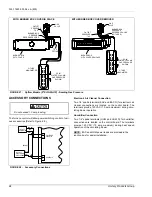

OPERATION AND MAINTENANCE

SEQUENCE OF OPERATION

The following describes the sequence of operation of the fur-

nace. Refer to the schematic wiring diagram in the back of

this manual for component location.

CONTINUOUS BLOWER

On cooling/heating thermostats with fan switch, when the fan

switch is set in the ON position, a circuit is completed

between terminals R and G of the thermostat. The blower

motor is energized through the low heat terminal and runs on

the selected speed. This allows constant air circulation at

lower flow rate.

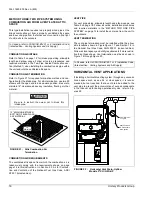

TABLE 8: FILTER PERFORMANCE - PRESSURE DROP INCHES W.C.

Airflow Range

Minimum Opening Size

(in.

2

)

Filter Type

Disposable

Hogs Hair

*

Pleated

1 Opening

2 Openings

1 Opening

2 Openings

1 Opening

2 Openings

1 Opening

2 Openings

0 - 750

230

0.01

0.01

0.15

751 - 1000

330

0.04

0.03

0.20

1001 - 1250

330

0.08

0.07

0.20

1251 - 1500

330

0.08

0.07

0.25

1501 - 1750

380

658

0.14

0.08

0.13

0.06

0.30

0.17

1751 - 2000

380

658

0.17

0.09

0.15

0.07

0.30

0.17

2001 & Above

463

658

0.17

0.09

0.15

0.07

0.30

0.17

*.

Hogs Hair Filters are the type supplied with furnace (if supplied).