3.6

Minimizing Positioning Time

121

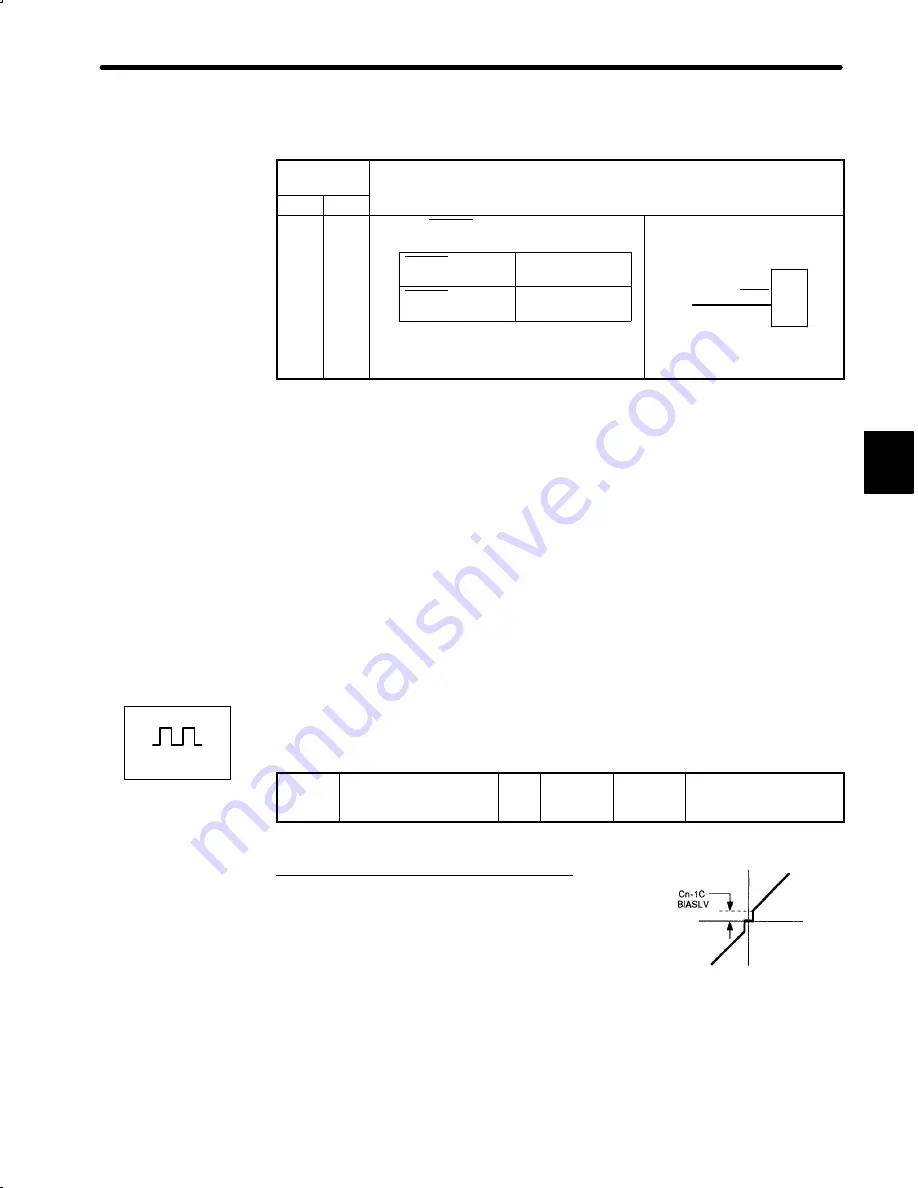

For speed/torque control only.

Cn-01

Setting

Control Mode

Bit B Bit A

Control Mode

D

Signal P-CON (1CN-41) is used to switch

between P control and PI control.

P-CON (1CN-41)

is open (OFF)

PI control

DR2 Servopack

P/PI

0

0

P-CON (1CN-41)

is closed (ON)

P control

P/PI

changeover

P-CON

(1CN-41)

(1CN 41)

D

Torque reference input T-REF (1CN-9)

cannot be used.

2) Proportional control can be used in the following two ways.

a) The host controller can selectively use P control mode for particular conditions only.

This method can prevent the occurrence of overshoot and also shorten settling time.

For particular conditions, refer to

3.6.6 Using Mode Switch

.

b) In the speed control mode, if PI control mode is used when the speed reference has a

reference offset, the motor may rotate at a very slow speed and fail to stop even if 0 is

specified as a speed reference. In this case, use P control mode to stop the motor.

3.6.5 Setting Speed Bias

The settling time for positioning can be reduced by assigning bias to the speed reference out-

put part in the Servopack. To assign bias, use the following constant.

Cn-1C

BIASLV

Bias

Unit:

r/min

Setting

Range: 0

to 450

Factory

Setting: 0

For Position Control

Only

This user constant is for position control only.

This user constant is set to assign an offset to a

speed reference in the DR2 Servopack.

Use this constant to shorten settling time.

Set this user constant according to machine conditions.

3

Positions

Internal speed

reference

Error pulse