7 FRONT AXLE

7 FRONT AXLE

EF494T TM 06/2011 edition

167

(3)

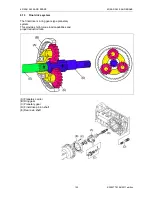

Set up a spring balance as shown in the

drawing on the right. Measure the torque

created when the drive pinion starts

rotating.

(4)

Tighten the seal collar little by little until the

torque reaches the specified level of 0.032

to 0.160 kgf-m. Make sure to measure the

torque repeatedly.

IMPORTANT

The seal collar should be replaced with a new

one.

If the torque is less than specified, the gear

may be damaged.

If the torque is greater than specified, the

bearing may be damaged.

(5)

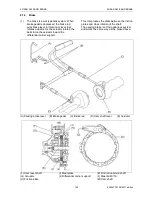

After the adjustments are finished, tap

section (A) and the opposite side on the

seal collar using a screwdriver to create

detents.

Summary of Contents for EF-494T

Page 1: ...EF494T TM 06 2011 edition ...

Page 85: ...3 ENGINE 3 ENGINE EF494T TM 06 2011 edition 77 3 ENGINE ...

Page 88: ...3 ENGINE 3 ENGINE EF494T TM 06 2011 edition 80 B Return ...

Page 126: ...4 CLUTCH 4 CLUTCH EF494T TM 06 2011 edition 118 4 CLUTCH ...

Page 130: ...4 CLUTCH 4 CLUTCH EF494T TM 06 2011 edition 122 ...

Page 133: ...5 TRANSMISSION 5 TRANSMISSION EF494T TM 06 2011 edition 125 5 TRANMISSION ...

Page 167: ...7 FRONT AXLE 7 FRONT AXLE EF494T TM 06 2011 edition 159 7 FRONT AXLE ...

Page 169: ...7 FRONT AXLE 7 FRONT AXLE EF494T TM 06 2011 edition 161 7 2 CROSS SECTION VIEW ...

Page 176: ...8 POWER STEERING 8 POWER STEERING EF494T TM 06 2011 edition 168 8 POWER STEERING ...

Page 234: ...11 APPENDIXES 11 APPENDIXES EF494T TM 06 2011 edition 226 11 APPENDIXES ...

Page 235: ...11 APPENDIXES 11 APPENDIXES EF494T TM 06 2011 edition 227 11 1 HYDRAULIC CIRCUIT DIAGRAM ...

Page 236: ...228 11 2 ELECTRICAL CIRCUIT DIAGRAM 11 2 1 WIRING HARNESS ...

Page 238: ...230 11 2 3 ELECTRICAL WIRING DIAGRAM ...

Page 239: ......