3 ENGINE

3 ENGINE

EF494T TM 06/2011 edition

109

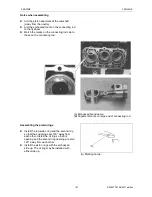

Engine compression pressure

(1)

After warming up the engine, stop it and

remove the air cleaner and all the fuel

injectors.

(2)

Install the diesel engine compression

gauge in the injector hole of each cylinder.

(3)

Move the accelerator lever to the STOP

position (the zero position for fuel injection)

and operate the starting motor for 5-10

seconds (at 200-300 rpm). Read the

maximum value when the gauge has

stabilized. Make the measurement twice.

(4)

If the pressure is below the operating limit,

put 2 cc of engine oil through the nozzle

hole. Idle the engine for a while to let the oil

penetrate and check the pressure again.

(5)

If the compression pressure returns to

normal, check the cylinder, piston, and

piston ring.

(6)

If the compression pressure does not

return to normal, check the valve and

cylinder head and related parts.

Compression pressure

Condition

Battery fully charged

Valve clearance is normally 0.2 mm, permitting the self-

starting motor to run at 300 rpm.

Criteria

30-35 kg/cm

2

(426-497 lb/sq.in)

Limit

30-35 kg/cm

2

(426-497 lb/sq.in)

Tolerance

10% max difference between cylinders

Summary of Contents for EF-494T

Page 1: ...EF494T TM 06 2011 edition ...

Page 85: ...3 ENGINE 3 ENGINE EF494T TM 06 2011 edition 77 3 ENGINE ...

Page 88: ...3 ENGINE 3 ENGINE EF494T TM 06 2011 edition 80 B Return ...

Page 126: ...4 CLUTCH 4 CLUTCH EF494T TM 06 2011 edition 118 4 CLUTCH ...

Page 130: ...4 CLUTCH 4 CLUTCH EF494T TM 06 2011 edition 122 ...

Page 133: ...5 TRANSMISSION 5 TRANSMISSION EF494T TM 06 2011 edition 125 5 TRANMISSION ...

Page 167: ...7 FRONT AXLE 7 FRONT AXLE EF494T TM 06 2011 edition 159 7 FRONT AXLE ...

Page 169: ...7 FRONT AXLE 7 FRONT AXLE EF494T TM 06 2011 edition 161 7 2 CROSS SECTION VIEW ...

Page 176: ...8 POWER STEERING 8 POWER STEERING EF494T TM 06 2011 edition 168 8 POWER STEERING ...

Page 234: ...11 APPENDIXES 11 APPENDIXES EF494T TM 06 2011 edition 226 11 APPENDIXES ...

Page 235: ...11 APPENDIXES 11 APPENDIXES EF494T TM 06 2011 edition 227 11 1 HYDRAULIC CIRCUIT DIAGRAM ...

Page 236: ...228 11 2 ELECTRICAL CIRCUIT DIAGRAM 11 2 1 WIRING HARNESS ...

Page 238: ...230 11 2 3 ELECTRICAL WIRING DIAGRAM ...

Page 239: ......