– 71 –

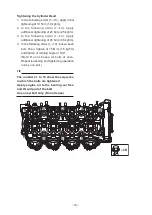

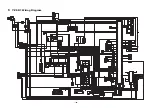

Installing the Crankcase

1. T i g hte n t h e b o l t s i n t h e t i g hte n i n g

sequence of 1 to 10 to 20 N•m (2.0 kg•m).

2. After loosening the bolts once in the

tightening sequence of 1 to 10, retighten

them one by one to 15 N•m (1.5 kg•m).

(Note: Do not loosen all bolts at once.

Repeat loosening and tightening operation

one by one bolt.)

3. Retighten the bolts in the tightening

sequence of 1 to 10 to a turn-of-nut angle

of 75°±5°.

4. T i g hte n t h e b o l t s i n t h e t i g hte n i n g

sequence of 11 to 20 to 24±2 N•m (2.4±0.2

kgf•m).

5. T i g hte n t h e b o l t s i n t h e t i g hte n i n g

sequence of 21 to 40 to 10±2 N•m (1.0±0.2

kgf•m).

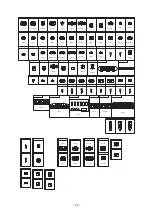

6

8

7

5

2

4

3

1

22

32

40

12

23

33

13

24

34

14

25

35

15

26

36

16

27

37

17

28

38

18

29

39

19

21

31

11

20

30

10

9

40

TIP

The numbers 1 to 40 show the sequence

in which the bolts are tightened.

Apply engine oil to the bolts 1 to 10, 21

to 27 and 29 to 39, and the both sides of

the washer. Apply screw rock agent to

the bolts 28 and 40 (apply engine oil to

the bearing surface only). Apply oil to the

thread part, bearing surface and O-RING

part of the bolts 11 to 20. Do not reuse a

mended O-RING.