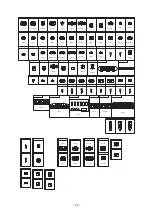

– 64 –

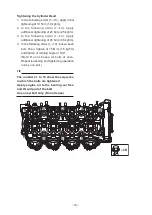

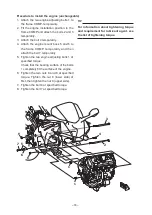

Engine

To be tightened

Part No.

Part Name Thread dia.

x

pitch

Tightening

torque N•m

(kgf•m)

Q’ty

Remarks

Install CLUTCH

BOSS

90179-20007

NUT

M20 x 1.0 125±5

(12.5±0.5)

1

APPLY OIL TO

BOTH SCREW

THREAD AND

BEARING.

1 POINT SWAG-

ING AFTER

TIGHTENING

Install CLUTCH

SPRING

2CR-16337-00

SCREW,

SPRING1

M6 x 1.0

10±2

(1.0±0.2)

3

Install

BEARING

HOUSING

90149-06082

SCREW

M6 x 1.0

12±2

(1.2±0.2)

3

APPLY TO SCREW

ROCKING

Tighten DRIVE

SPROCKET

90179-22018

NUT

M22x 1.0

125±10

(12.5±1.0)

1

2 POINT SWAG-

ING AFTER

TIGHTENING

Install

STOPPER,

SHIFT BAR and

PLATE,

STOPPER 2

90149-06158

SCREW

M6 x 1.0

10±2

(1.0±0.2)

2

APPLY TO SCREW

ROCKING

Install

STOPPER

SCREW

1D7-18127-00

STOPPER,

SCREW

M8 x 1.25 22±2

(2.2±0.2)

1

APPLY TO SCREW

ROCKING

Install ARM,

SHIFT

90105-06127

BOLT,

FLANGE

M6 x 1.0

10±2

(1.0±0.2)

1

CHECK SERRA-

TION FOR

TIGHTENING

UP

Install SENSOR,

GEAR POSITION

90110-05067

BOLT,

HEXAGON

SOCKET

M5 x 0.8

3 – 5

(0.3 – 0.5)

2

APPLY TO SCREW

ROCKING

Install

NEUTRAL

SWITCH

3GB-82540-01

NEUTRAL

SWITCH

ASSY.

M10 x

1.25

17±3

(1.7±0.3)

1

OVERTIGHTEN-

ING MAY DAM-

AGE THE PART

Install COVER,

SERVOMOTOR

97702-50514

SCREW,

TRUSS

HEAD TAP-

PING

M5

1 – 3

(0.1 – 0.3)

2

Install THERMO

SENSOR

(for water

temperature)

4P9-83591-00

THERMO

SENSOR

ASSY

M10 x

1.25

16±2

(1.6±0.2)

1

SENSOR, CAM

POSITION

90110-06175

BOLT,

HEXAGON

SOCKET

HEAD

M6 x 1.0

7.5±1.5

(0.75±0.15)

1

APPLY TO SCREW

ROCKING