– 32 –

NOTICE

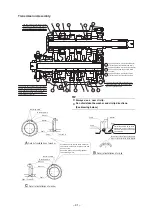

When fitting the camshaft, use the slotted

holes of the cam sprockets and always

set the timing to match. If otherwise, no

intended performance can be expected and

more over, the engine may be damaged.

TIP

Install the cam sprocket as the scratch

line and BX4 mark face the outside of the

engine.

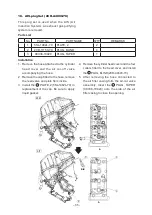

Installation

1. Fit the scratch line on the camshaft to the

compression top dead point 105 degree (K

mark position) to combine the camshaft

and cylinder head surface.

2. Adjust the valve timing (to the value stated

on the normal specifications) using the

long holes.

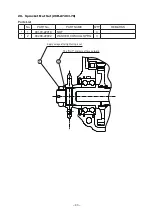

<How to position at #1 cylinder’s compression top dead point 105°>

< Position to install the cam sprocket at #1 cylinder compression top dead point 105°>

#1

#2

#3

#4

Exhaust side

Intake side

Fit the assembly (K) mark of the rotor

assembly to the case surface line.

(#1 cylinder compression top dead

point 105 degree)

Intake #1 cam nose

Intake valve timing mark

(Scratch line)

Tighten using the long holes on the cam sprocket.

Exhaust #1 cam nose

Exhaust valve timing mark

(Scratch line)