– 41 –

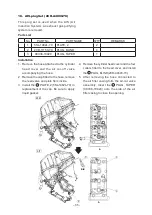

Transmission Assembly

M1

M1

M1

M2

M2

M2

M1

M2

M3

M3

M3

M3

A

B

B

B B

B

C

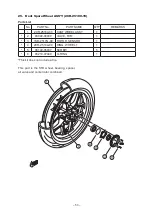

Rotate washer so that its teeth meet axle-

spline teeth on the axle, and then lock with

washer,s claw.

Assemble washer with putting together

their matching mark.

Apply molybdenum oil to inside of diameter.

After assembly, it should rotate smoothly.

Apply molybdenum oil to the inside diameter

and end. After assembly, it should rotate

smoothly.

Apply molybdenum oil to teeth of spline.

After assembly, it should slide smoothly.

The seal side should face outward (one

side seal bearing) and assembled toward

the case right side edge.

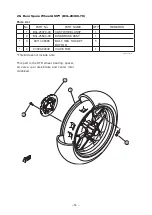

Position the center of the abutment joint

of the circlip right with the spline threads.

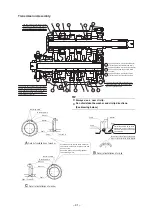

Circlip

Shaft

Edge

PortionR

Edge

Detail of installation of washer

Detail of installation of washer

Shaft

Washer

Washer

Matching mark

Matching mark

Portion R

Washer

Gear

The seal side should face outward

(one side seal bearing) and press

in the bearing cup all the way into

the case until it touches bottom.

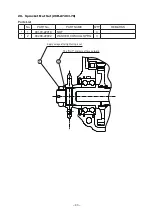

Points to be careful of the oil seal assembly

The convex part on the oil seal should be

put into the case groove vertically so that

the oil seal does not fall over and is tightly

fit into the bearing cup of the bearing.

(Apply grease to the lip.)

Detail of installation of circlip

Edge

Shaft

Washer

Washer

Matching mark

Matching mark

Portion R

TIP

•

Always use a new circlip.

•

Do not mistake the washer and circlip directions.

(See drawing below.)

Install the circlip with its inner

diameter R portion to the gear

side and its edge portion to the

opposite side.