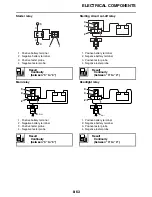

ELECTRICAL COMPONENTS

8-60

Refer to “GENERAL CHASSIS” on page 4-1.

EAM30291

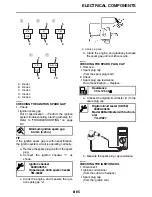

CHECKING AND CHARGING THE BATTERY

WARNING

EWA13290

Batteries generate explosive hydrogen gas

and contain electrolyte which is made of poi-

sonous and highly caustic sulfuric acid.

Therefore, always follow these preventive

measures:

• Wear protective eye gear when handling or

working near batteries.

• Charge batteries in a well-ventilated area.

• Keep batteries away from fire, sparks or

open flames (e.g., welding equipment,

lighted cigarettes).

• DO NOT SMOKE when charging or han-

dling batteries.

• KEEP BATTERIES AND ELECTROLYTE

OUT OF REACH OF CHILDREN.

• Avoid bodily contact with electrolyte as it

can cause severe burns or permanent eye

injury.

FIRST AID IN CASE OF BODILY CONTACT:

EXTERNAL

• Skin — Wash with water.

• Eyes — Flush with water for 15 minutes and

get immediate medical attention.

INTERNAL

• Drink large quantities of water or milk fol-

lowed with milk of magnesia, beaten egg or

vegetable oil. Get immediate medical atten-

tion.

NOTICE

ECA13661

• This is a VRLA (Valve Regulated Lead Acid)

battery. Never remove the sealing caps be-

cause the balance between cells will not be

maintained and battery performance will

deteriorate.

• Charging time, charging amperage and

charging voltage for a VRLA (Valve Regu-

lated Lead Acid) battery are different from

those of conventional batteries. The VRLA

(Valve Regulated Lead Acid) battery should

be charged according to the appropriate

charging method. If the battery is over-

charged, the electrolyte level will drop con-

siderably. Therefore, take special care

when charging the battery.

TIP

Since VRLA (Valve Regulated Lead Acid) bat-

teries are sealed, it is not possible to check the

charge state of the battery by measuring the

specific gravity of the electrolyte. Therefore, the

charge of the battery has to be checked by mea-

suring the voltage at the battery terminals.

1. Remove:

•

Side cover (left/right)

•

Seat

Refer to “GENERAL CHASSIS” on page 4-1.

2. Disconnect:

•

Battery lead

(from the battery terminals)

NOTICE

ECA13700

First, disconnect the negative battery lead,

and then the positive battery lead.

3. Remove:

•

Battery

4. Check:

•

Battery charge

a. Connect a digital circuit tester to the bat-

tery terminals.

TIP

•

The charge state of a VRLA (Valve Regulated

Lead Acid) battery can be checked by measur-

ing its open-circuit voltage (i.e., the voltage

when the positive battery terminal is discon-

nected).

•

No charging is necessary when the open-cir-

cuit voltage equals or exceeds 12.8 V.

b. Check the charge of the battery, as shown

in the charts and the following example.

•

Positive tester probe

positive battery terminal

•

Negative tester probe

negative battery terminal

Example

Open-circuit voltage = 12.0 V

Charging time = 6.5 hours

Charge of the battery = 20–30 %

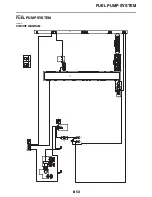

Summary of Contents for WR250F 2022

Page 5: ...EAM20093 YAMAHA MOTOR CORPORATION U S A WR MOTORCYCLE LIMITED WARRANTY...

Page 8: ......

Page 10: ......

Page 41: ...MULTI FUNCTION DISPLAY 1 29...

Page 62: ...ELECTRICAL SPECIFICATIONS 2 9 Radiator fan motor fuse 5 0 A Spare fuse 15 0 A...

Page 70: ...CABLE ROUTING DIAGRAM 2 17 EAM20152 CABLE ROUTING DIAGRAM Frame and engine left side view...

Page 72: ...CABLE ROUTING DIAGRAM 2 19 Frame and engine right side view...

Page 74: ...CABLE ROUTING DIAGRAM 2 21 Handlebar front view...

Page 76: ...CABLE ROUTING DIAGRAM 2 23 Frame and engine top view...

Page 78: ...CABLE ROUTING DIAGRAM 2 25 Frame and battery top view...

Page 80: ...CABLE ROUTING DIAGRAM 2 27 Rear brake right side view...

Page 82: ...CABLE ROUTING DIAGRAM 2 29 Front brake front view and right side view...

Page 84: ...CABLE ROUTING DIAGRAM 2 31 Taillight top view and right side view...

Page 86: ...CABLE ROUTING DIAGRAM 2 33...

Page 204: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 5 3 1 Oil filter element 2 Oil pump...

Page 205: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 5 4 1 Intake camshaft 2 Exhaust camshaft...

Page 278: ...TRANSMISSION 5 77...

Page 288: ...WATER PUMP 6 9...

Page 298: ...THROTTLE BODY 7 9...

Page 301: ......

Page 302: ...IGNITION SYSTEM 8 1 EAM20142 IGNITION SYSTEM EAM30277 CIRCUIT DIAGRAM...

Page 306: ...ELECTRIC STARTING SYSTEM 8 5 EAM20143 ELECTRIC STARTING SYSTEM EAM30279 CIRCUIT DIAGRAM...

Page 312: ...CHARGING SYSTEM 8 11 EAM20144 CHARGING SYSTEM EAM30282 CIRCUIT DIAGRAM...

Page 315: ...CHARGING SYSTEM 8 14...

Page 316: ...SIGNALING SYSTEM 8 15 EAM20154 SIGNALING SYSTEM EAM30348 CIRCUIT DIAGRAM...

Page 320: ...LIGHTING SYSTEM 8 19 EAM20153 LIGHTING SYSTEM EAM30346 CIRCUIT DIAGRAM...

Page 323: ...LIGHTING SYSTEM 8 22...

Page 324: ...COOLING SYSTEM 8 23 EAM20155 COOLING SYSTEM EAM30350 CIRCUIT DIAGRAM...

Page 327: ...COOLING SYSTEM 8 26...

Page 328: ...FUEL INJECTION SYSTEM 8 27 EAM20145 FUEL INJECTION SYSTEM EAM30284 CIRCUIT DIAGRAM...

Page 353: ...FUEL INJECTION SYSTEM 8 52...

Page 354: ...FUEL PUMP SYSTEM 8 53 EAM20146 FUEL PUMP SYSTEM EAM30287 CIRCUIT DIAGRAM...

Page 388: ...SELF DIAGNOSTIC FUNCTION AND DIAGNOSTIC CODE TABLE 9 15...

Page 398: ...CHASSIS 10 9...

Page 400: ......

Page 402: ......