–58–

CARBURETORS

CARB

NOTE:

NOTE:

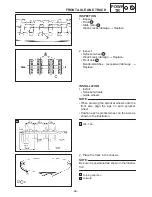

ASSEMBLY

Reverse the “DISASSEMBLY” procedure. Note

the following points.

Before reassembling, wash all parts in clean

gasoline.

Always use a new gasket and O-ring.

1. Tighten:

Inner parts

Pilot air jet / main air jet:

0.7 Nm (0.07 m

kg, 0.5 ft

lb)

Screw (valve seat):

1 Nm (0.1 m

kg, 0.7 ft

lb)

Pilot jet:

0.7 Nm(0.07 m

kg, 0.5 ft

lb)

Main jet:

1.8 Nm (0.18 m

kg, 1.3 ft

lb)

Starter plunger assembly:

2.5 Nm (0.25 m

kg, 1.8 ft

lb)

2. Measure:

Float height

a

Out of specification

Adjust.

Float height

a

:

21.3

23.3 mm

(0.839

0.917 in)

Measurement and adjustment steps:

Hold the carburetor in an upside down posi-

tion.

Measure the distance between the carburetor

body and top of the floats.

The float arm should be resting on the valve, but

no compressing the needle valve.

If the float height is not within specification, in-

spect the valve seat and needle valve.

If either is worn, replace them both.

If both are fine, adjust the float height by bend-

ing the float arm tang

1

on the float.

Recheck the float height.

Summary of Contents for SX500D

Page 1: ...SUPPLEMENTARY SERVICE MANUAL ...

Page 85: ... 81 CABLE ROUTING SPEC CABLE ROUTING 500 ...

Page 87: ... 83 CABLE ROUTING SPEC ...

Page 89: ... 85 CABLE ROUTING SPEC ...

Page 91: ... 87 CABLE ROUTING SPEC ...

Page 93: ... 89 CABLE ROUTING SPEC ...

Page 95: ... 91 CABLE ROUTING SPEC ...

Page 97: ... 93 CABLE ROUTING SPEC CABLE ROUTING 600 700 ...

Page 99: ... 95 CABLE ROUTING SPEC ...

Page 101: ... 97 CABLE ROUTING SPEC ...

Page 103: ... 99 CABLE ROUTING SPEC ...

Page 105: ... 101 CABLE ROUTING SPEC ...

Page 107: ... 103 CABLE ROUTING SPEC ...

Page 109: ... 105 CABLE ROUTING SPEC ...

Page 112: ...WIRING DIAGRAM ...

Page 114: ...WIRING DIAGRAM ...