–39–

BRAKE

POWR

TR

CAUTION:

NOTE:

NOTE:

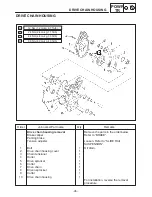

Disc brake components rarely require dis-

assembly. DO NOT:

Disassemble components unless abso-

lutely necessary.

Use solvents on internal brake compo-

nents.

Use contaminated brake fluid for cleaning.

Use only clean brake fluid.

Allow brake fluid to come in contact with

the eyes, otherwise eye injury may occur.

Allow brake fluid to contact painted sur-

faces or plastic parts otherwise damage

may occur.

Disconnect any hydraulic connection of-

herwise the entie system must be disas-

sembled, drained, cleaned, and then prop-

erly filled and bled after reassembly.

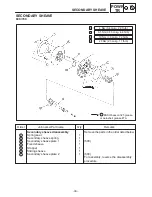

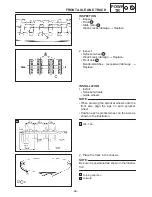

BRAKE PAD REPLACEMENT

It is not necessary to disassemble the brake cal-

iper and brake hose to replace the brake pads.

1. Remove:

Brake pads

1

Do not depress the brake lever when the cali-

per or disc is off the machine otherwise the

brake pads will be forced shut.

Install new brake pad spring and shims when

the brake pads have to be replaced.

Replace the pads as a set if either is found to

be worn to the wear limit

a

.

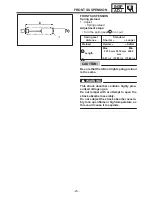

Wear limit

a

:

4.7 mm (0.17 in)

Summary of Contents for SX500D

Page 1: ...SUPPLEMENTARY SERVICE MANUAL ...

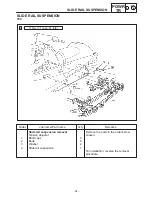

Page 85: ... 81 CABLE ROUTING SPEC CABLE ROUTING 500 ...

Page 87: ... 83 CABLE ROUTING SPEC ...

Page 89: ... 85 CABLE ROUTING SPEC ...

Page 91: ... 87 CABLE ROUTING SPEC ...

Page 93: ... 89 CABLE ROUTING SPEC ...

Page 95: ... 91 CABLE ROUTING SPEC ...

Page 97: ... 93 CABLE ROUTING SPEC CABLE ROUTING 600 700 ...

Page 99: ... 95 CABLE ROUTING SPEC ...

Page 101: ... 97 CABLE ROUTING SPEC ...

Page 103: ... 99 CABLE ROUTING SPEC ...

Page 105: ... 101 CABLE ROUTING SPEC ...

Page 107: ... 103 CABLE ROUTING SPEC ...

Page 109: ... 105 CABLE ROUTING SPEC ...

Page 112: ...WIRING DIAGRAM ...

Page 114: ...WIRING DIAGRAM ...