MIDDLE GEAR

5-90

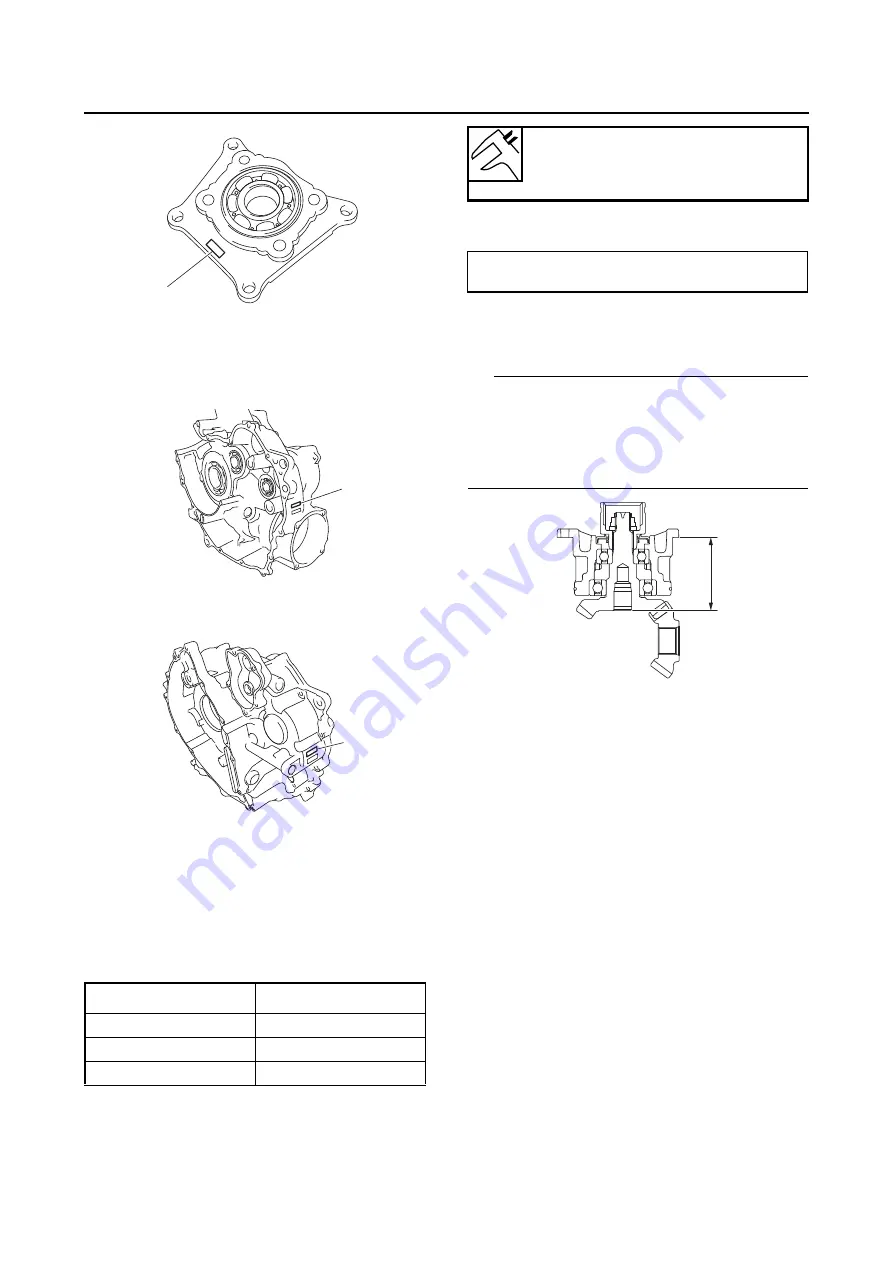

“b” is 17.0

“c” is 55.0

If the crankcase (right) is marked “64.96”,

“d” is 64.96

If the crankcase (left) is marked “9.01”,

“e” is 9.01

Therefore, “A” is 1.39.

“A” = 9.01 + 64.96 - 17.0 - 55.0 - 0.58

= 1.39

Round off hundredths digit and select appro-

priate shim(s).

In the above example, the calculated shim

thickness is 1.39 mm. The following chart in-

structs you, however, to round off 9 to 10.

Shims are supplied in the following thickness-

es.

c. To find middle driven pinion gear shim thick-

ness “B”, use the following formula.

“f” = a numeral (usually a decimal number) on

the bearing housing is either added to or sub-

tracted from “77.5”

TIP

After replacing any part in the middle driven pin-

ion gear assembly, the overall length of the as-

sembly will change. Therefore, be sure to

measure distance “f” to select the correct middle

driven pinion gear shim thickness.

“g” = a numeral (usually a decimal number)

on the middle driven pinion gear is either add-

ed to or subtracted from “49.0”

“h” = a numeral (usually a decimal number)

on the middle driven pinion gear is either add-

ed to or subtracted from “80.5”

“i” = a numeral (usually a decimal number) on

the left crankcase specifies a thickness of

“99.98”

“j” = a numeral (usually a decimal number) on

the right crankcase specifies a thickness of

“8.12”

Example:

If the bearing housing is marked “+03”,

“f” is 77.53

Hundredth

Rounded value

0, 1, 2

0

3, 4, 5, 6, 7

5

8, 9

10

a

d

e

Middle drive pinion gear shim

Thickness (mm)

0.50 0.55 0.60 0.70 0.80 0.90 1.00

Middle driven pinion gear shim thickness

“B” = “f” - “g” + “h” - “i” - “j”

f

Summary of Contents for 2016 Grizzly yf700gg

Page 6: ......

Page 8: ......

Page 11: ...IDENTIFICATION 1 2 ...

Page 37: ...ENGINE SPECIFICATIONS 2 6 Air induction system Solenoid resistance 18 22 Ω ...

Page 58: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 27 EBS30023 LUBRICATION DIAGRAMS 6 7 8 9 3 4 3 2 1 5 ...

Page 60: ...LUBRICATION SYSTEM CHART AND DIAGRAMS 2 29 1 2 3 4 5 ...

Page 62: ...COOLING SYSTEM DIAGRAMS 2 31 EBS20021 COOLING SYSTEM DIAGRAMS 1 2 3 10 9 8 6 7 5 4 ...

Page 78: ...CABLE ROUTING 2 47 Front and rear brake hoses F 3 F 3 F 3 3 I G H 4 4 B C D 2 E D 2 A 1 ...

Page 80: ...CABLE ROUTING 2 49 ...

Page 83: ......

Page 119: ...PERIODIC MAINTENANCE 3 36 A Headlight left and right B Handle mounted light b a 1 A b a 1 B ...

Page 120: ...PERIODIC MAINTENANCE 3 37 ...

Page 197: ...REAR ARMS AND REAR SHOCK ABSORBER ASSEMBLIES 4 74 7 9 8 9 7 3 5 4 5 3 6 2 10 10 1 ...

Page 198: ...REAR ARMS AND REAR SHOCK ABSORBER ASSEMBLIES 4 75 ...

Page 203: ...ENGINE INSPECTION 5 2 Top cover Refer to GENERAL CHASSIS 2 on page 4 6 ...

Page 244: ...ELECTRIC STARTER 5 43 a b b 1 2 3 ...

Page 316: ...AIR INDUCTION SYSTEM 7 9 EBS20057 AIR INDUCTION SYSTEM 3 4 1 2 3 4 1 2 ...

Page 352: ...REAR CONSTANT VELOCITY SHAFT ASSEMBLIES FINAL DRIVE ASSEMBLY AND REAR DRIVE SHAFT 8 31 ...

Page 355: ......

Page 365: ...ELECTRIC STARTING SYSTEM 9 10 ...

Page 369: ...CHARGING SYSTEM 9 14 ...

Page 417: ...FUEL PUMP SYSTEM 9 62 ...

Page 434: ...ELECTRICAL COMPONENTS 9 79 1 2 3 5 7 8 9 10 11 12 13 14 15 16 17 18 19 4 6 ...

Page 454: ...ELECTRICAL COMPONENTS 9 99 ...

Page 468: ......

Page 469: ......

Page 470: ......