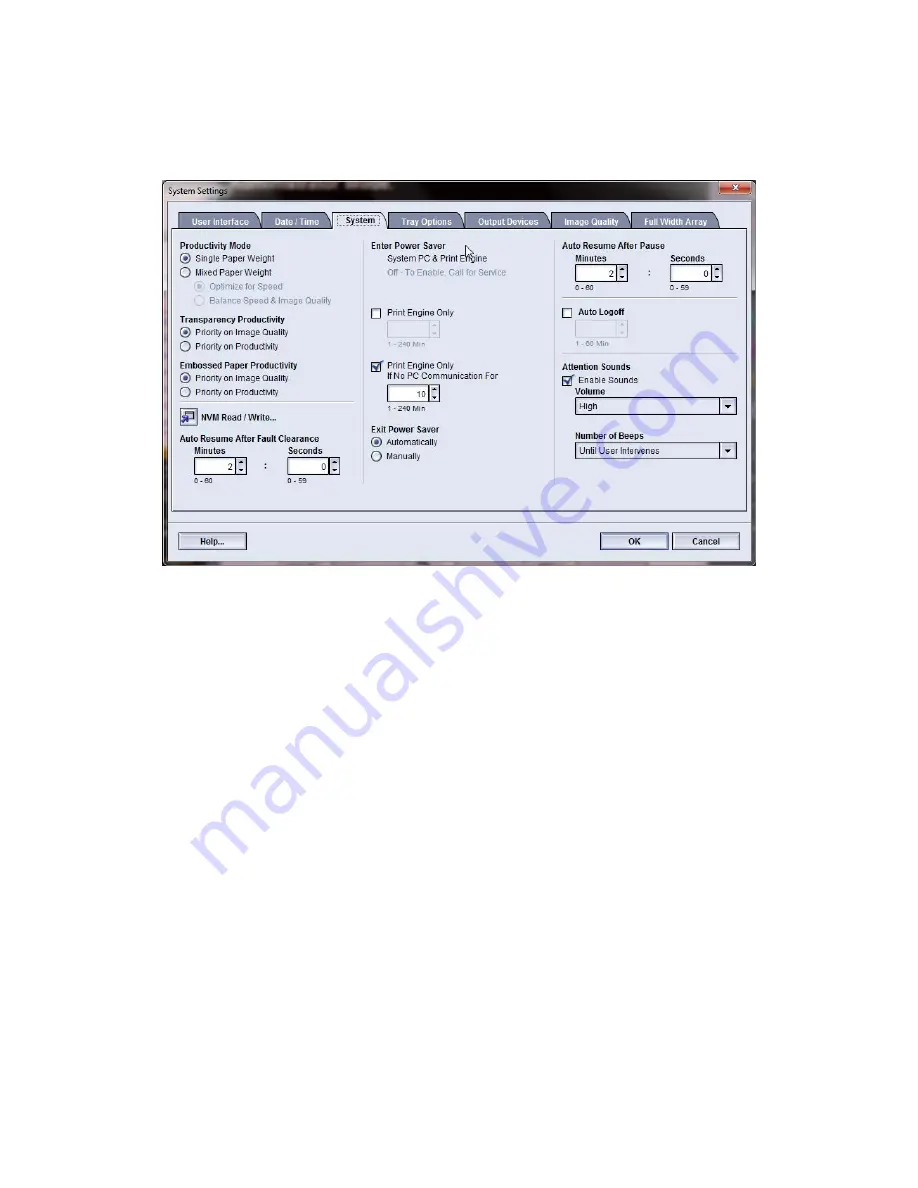

System

Use this feature to change the factory default settings for the following:

• Productivity Mode, includes:

-

Single Paper Weight

-

Mixed Paper Weight

-

Transparency Productivity

-

Embossed Paper Productivity

• Power Saver mode

• Auto Resume

• Auto Logoff

• Attention Sounds

The System feature also allows you to enter NVM Read/Write values when using

specialized media.

5-9

Xerox

®

Color 800/1000 Press

System Administration Guide

System Settings