Dealer Service

23

MAN1279 (15/04/2019)

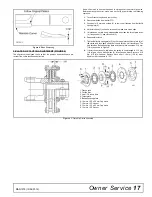

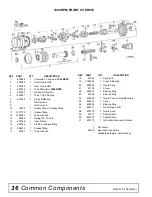

SPLITTER GEARBOX REPAIR

(Figure 14)

Removal from Cutter

1.

Disconnect and remove all drivelines from gearbox.

2.

Remove the four cap screw and lock washers that secure gearbox to

cutter, and remove gearbox.

NOTE:

Gearbox is heavy: do not attempt to move it without mechanical

assistance.

Disassembly

Center Shaft

1.

Remove plug from side of gearbox and pour out the gear oil.

2.

Remove seal (6, to be replaced) from the front and rear of the center

shaft (5).

3.

Remove front cap (4) and gaskets (8, 9, 10) from the front and rear of the

center shaft (5).

4.

Support gearbox in a hand press and push on the rear of the center shaft.

5.

Remove bearing cones (7), and gear (18) from center shaft (5).

6.

Remove bearing cups (7) from housing and cap using a punch and

hammer.

Side Shaft

7.

Remove seal (12, to be replaced) from the output shaft (13).

8.

Remove 8 cap screws (3) and side shaft assembly.

9.

Remove cotter pin (21), bearing adjustment nut (20), and gear (19).

10.

Support side shaft assembly in hand press. Press shaft (13) through the

cap (11) from the threaded end of the shaft.

11.

Repeat steps 10 through 12 for opposite side shaft.

Inspect Components

12.

Inspect gears for broken teeth and wear. Some wear is normal and will

show on the loaded side of the teeth. Forged gear surfaces are rough

when new. Check that wear pattern is smooth.

13.

Inspect shafts for grooves, nicks, or bumps in the areas where seals seat.

Resurface any damage with emery cloth or replace shaft.

14.

Inspect housing and caps for cracks or other damage.

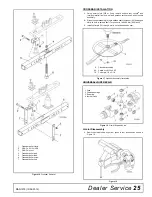

Assembly

1.

Clean housing, pay specific attention to areas where gaskets are

installed.

2.

Wash housing and all components thoroughly.

3.

Select a clean work area to assemble gearbox.

4.

Replace all seals, bearings, and gaskets.

5.

All parts must be clean and lightly oiled before assembly.

Side Shaft

6.

Insert bearing cups (7) in hub cap (11) using a round tube of the same

size diameter and a hand press.

7.

Press bearing cone (7) on to output shaft (13), slide output shaft (13)

through hub cap (11) and press bearing cone (7) on to output shaft (13).

8.

Slide gear (19) over output shaft (13) and secure with nut (20) and cotter

pin (21).

9.

Check end play of shaft by moving it in and out. If end play is more than

0.305 mm (0.012 in.), tighten nut (20). Repeat process until end play is

less than 0.305 mm (0.012 in).

10.

Check rotational torque. Torque should be less than 2.2 lbs-inch gear.

11.

Place seal (12) over shaft and press into housing using a tube of the

same diameter. Seal should be flush with housing when properly

installed.

12.

Repeat steps 6 through 10 for opposite side shaft.

Center Shaft

13.

Insert bearing cups (7) in housing and front cap (4) using a round tube of

the same size diameter and a hand press.

14.

Press spacer (14), gear (18), shims (15, 16, 17) and bearing cones (7) on

to input shaft (5).

15.

Slide input shaft (5) through housing and install gaskets (8, 9, 10) and

cap (4).

16.

Check end play of shaft by moving it in and out. If end play is more than

0.305 mm (0.012 in.), remove a gasket (8, 9, or 10). Repeat process until

end play is less than 0.305 mm (0.012 in).

17.

Check rotational torque. Torque should be less than 2.2 lbs-inch gear.

18.

Check gear backlash, backlash should be between 0.15 and 0.406 mm

(0.006 and 0.016 in). Adjust the backlash by adding or removing shims

(15, 16, 17) from the input shaft (5).

19.

Place seal (6) over shaft and press into housing using a tube of the same

diameter. Seal should be flush with housing when properly installed.

Repeat process for opposite end shaft

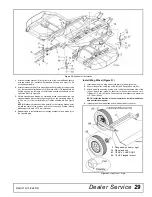

Gearbox Inspection

1.

Check gearbox for leaks by: plugging all holes except one, applying .275

bar (4 psi) of compressed air, and immersing gearbox in water. Verify

gearbox does not leak.

NOTE:

Excessive air pressure will damage seals.

2.

Remove gearbox from water and dry off.

3.

Remove upper plug on right side of housing. Add SAE 80W or 90W EP

oil until it runs out side level hole. Replace plug.

4.

Install breather (24) in top cover.

Gearbox Installation

NOTE:

Gearbox is heavy: do not attempt to move it without mechanical assis-

tance.

1.

Place gearbox on cutter and secure into position using four cap screws

and lock washers.

2.

Torque hardware to 406.75 N-m (300 lbs-ft).

3.

Attach all drivelines to gearbox.

4.

Install all shields.

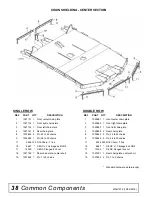

Summary of Contents for BATWING BW20.50QE

Page 1: ...OPERATOR S MANUAL BATWING ROTARY CUTTER Rev 22 10 2019 BW20 50QE BW20 60QE BW20 70QE MAN1279...

Page 10: ...10 Declaration of Conformity MAN1279 15 04 2019...

Page 45: ...Common Components 45 MAN1279 15 04 2019 NOTES...

Page 46: ...46 50 Series Parts MAN1279 15 04 2019 CENTER FRAME ASSEMBLY BW20 50QE...

Page 50: ...50 50 Series Parts MAN1279 15 04 2019 WING CENTER GEARBOX ASSEMBLY BW20 50QE...

Page 55: ...50 Series Parts 55 MAN1279 15 04 2019 NOTES...

Page 56: ...56 60 Series Parts MAN1279 15 04 2019 CENTER FRAME ASSEMBLY BW20 60QE...

Page 60: ...60 60 Series Parts MAN1279 15 04 2019 WING CENTER GEARBOX ASSEMBLY BW20 60QE...

Page 66: ...66 70 Series Parts MAN1279 15 04 2019 CENTER FRAME ASSEMBLY BW20 70QE...

Page 70: ...70 70 Series Parts MAN1279 15 04 2019 WING CENTER GEARBOX ASSEMBLY BW20 70QE...

Page 90: ...10 Declaration of Conformity MAN1279 15 04 2019 10 D claration de conformit MAN1279 15 04 2019...