4

Translation of the original instructions

BA000527 - 09/2013 (Rev. H)

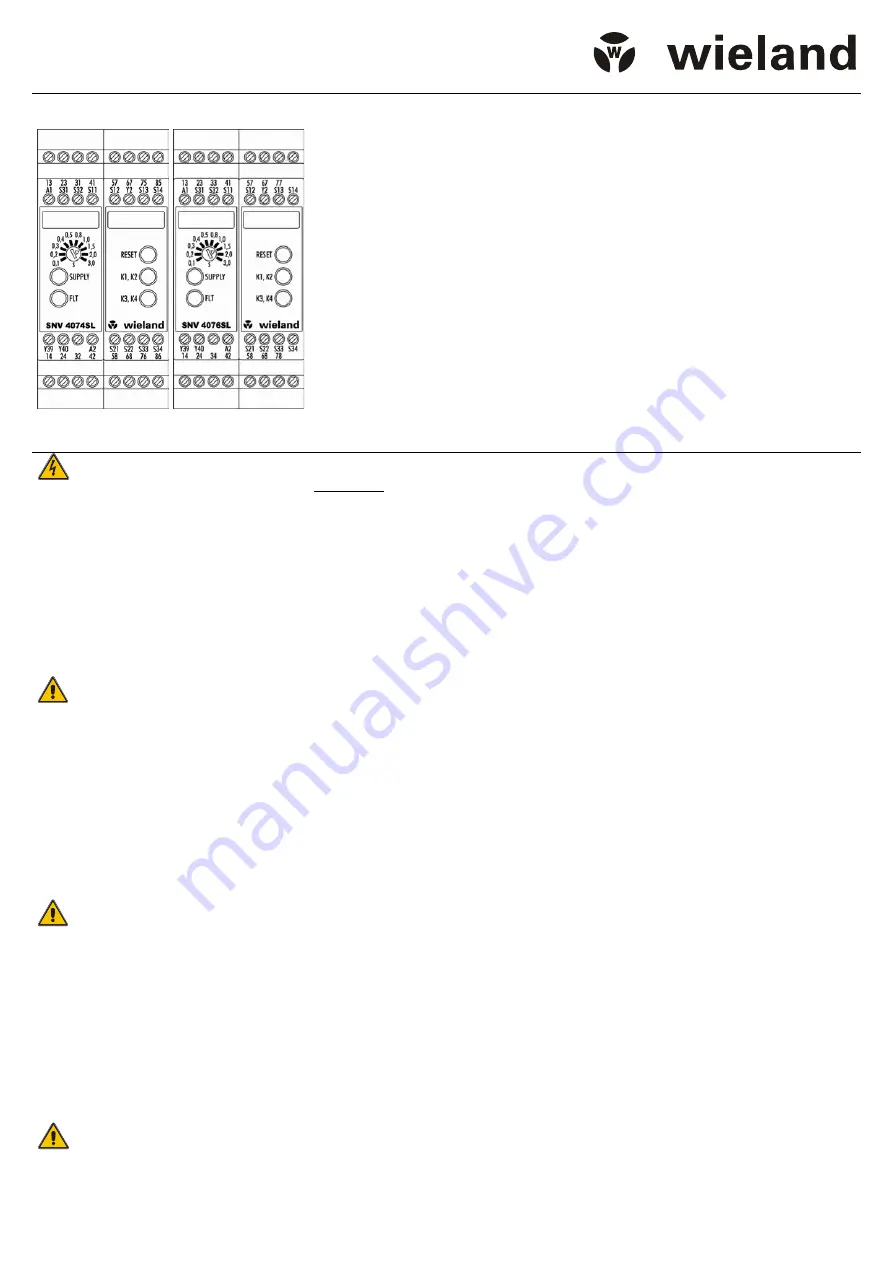

SNV 4074SL / -A / -C, SNV 4076SL / -A / -C

Basic device with release delay (OFF delay) for EMERGENCY STOP and safety door

applications

Basic device according to EN 60204-1:2005 and EN ISO 13849-1:2008 for single or two-

channel EMERGENCY STOP monitoring.

PL “e”/category 4 in accordance with EN ISO 13849-1:2008

SIL CL3 according to DIN EN 62061:2005

Stop Category 0 and 1 according to DIN EN 60204-1

Manual or automatic start with monitoring of the feedback loop of external contactors

With or without crossover detection

2 (3) not delayed and 2 (3) delayed enabling current paths

Discretely adjustable OFF delay with separate control input for the premature ending of the

OFF delay

For processing signals from output signal switching devices (OSSD) of a light grid according

to DIN EN 61496-1

Use in combustion plants according to EN 50156-1:2005 SNS 3

Power supply 24 V DC or 115-230 V AC

Device versions

SNV 4074SL: 0,1-3s / 0-30s / 0-300s

with fixed screw clamp terminals

SNV 4074SL-A: 0,1-3s / 0-30s / 0-300s

with pluggable screw clamp terminals

SNV 4074SL-C: 0,1-3s / 0-30s / 0-300s

with pluggable spring-loaded terminals

SNV 4076SL: 0,1-3s / 0-30s / 0-300s

with fixed screw clamp terminals

SNV 4076SL-A: 0,1-3s / 0-30s / 0-300s

with pluggable screw clamp terminals

SNV 4076SL-C: 0,1-3s / 0-30s / 0-300s

with pluggable spring-loaded terminals

Safety regulations

Device and function description

SNV 407xSL

The SNV 407xSL is an electronic, redundant and self-monitoring safety switching

device for EMERGENCY STOP equipment according to DIN EN 60204-1 with positively driven re-

lays.

Basic function:

After applying the supply voltage to the terminals A1/A2 and closed safety cir-

cuits, the enabling current paths are closed when a reset signal is established. The enabling cur-

rent paths are opened when the safety circuits are opened/de-energised.

Operating modes / System functions

Single or two-channel actuation

In the case of single-channel actuation, both the safety

circuits CH1 and CH2 are connected in parallel and are separated for two-channel actuation

(see Installation 1 to 4).

Without crossover detection

Both safety circuits are connected to positive potential (see

Installation 2).

With crossover detection

The safety circuit CH1 is connected to negative potential and the

safety circuit CH2 to positive potential (see Installation 3).

Reset function with starting lockout

The Reset button is connected between S33 and S34.

In order to activate the relay, the Reset button must be pressed and released again (trigger-

ing with falling edge). No enable is performed if the button is not released (see Installation

6).

Reset function without starting lockout

The reset input S14 is connected to S13. In the case

of closed feedback circuits, the relays activate with the closing of the safety circuits (see In-

stallation 5).

OSSD compatible

Output signal switching devices (OSSD) of a light barrier or other safety

sensors with semiconductor outputs can be processed. Test pulses which are < t

TP

do not in-

fluence the device functions. Test pulses > t

TP

can result in deactivation of the relays (see In-

stallation 4).

Release delay (OFF delay)

The OFF-delayed part (K3/K4) switches off after opening the safe-

ty circuits according to the specified delay time. Switching on again is not possible until after

expiry of the OFF delay.

Time-Clear

Premature ending of the OFF delay. If the connection Y39/Y40 is opened during

the time delay, the OFF delay is ended immediately and the relays K3/K4 switch off (see In-

stallation 7).

Feedback circuit

The feedback circuit of the not delayed and of the delayed part is connected

between S13/Y2 (see Installations 5 and 6).

Discrepancy time

Within this time, both the input signals of the safety circuits can have

different states without this resulting in the relays switching off.

Please also observe the information from your professional trade association!

The safety functions are not evaluated by UL. The approval is accomplished according to UL 508,

general use applications.

The installation, commissioning, modification

and retrofitting must only be performed by a

qualified electrician!

Disconnect the device / the system from the

power supply before starting work! In the case

of installation and system errors, mains voltage

can be present on the control circuit in the case

of non-galvanically isolated devices!

Observe the electrotechnical and professional

trade association safety regulations for the in-

stallation of the equipment.

Opening the case or other manipulation voids

any warranty.

Attention!

In the case of improper use or any use other

than for the intended purpose, the device must

no longer be used and any warranty claim is

void. Invalidating causes can be:

strong mechanical loading of the device such

as, e.g. in the case of falling or voltages, cur-

rents, temperatures, humidity outside the speci-

fication.

Please always check all safety functions in ac-

cordance with the applicable regulations during

initial commissioning of your machine / system

and observe the specified inspection cycles for

safety devices.

Attention!

Take the following safety precautions before

starting installation / assembly or dismantling:

1.

Disconnect the device / the system from

the power supply before starting work!

2.

Secure the machine / system against being

switched on again!

3.

Confirm that no voltage is present!

4.

Ground the phases and short to ground

briefly!

5.

Cover and shield neighbouring live parts!

6.

The devices must be installed in a switch

cabinet with a protection class of at least

IP 54.

Attention!

Limited contact protection! Degree of protection

according to DIN EN 60529.

Case/terminals: IP 40 / IP 20.

Finger-proof according to DIN VDE 0660 Part 514.