Benchmark 750-3000 Installation & Startup Manual

SECTION 2

– INSTALLATION

OMM-115_D

•

GF-200

•

5/9/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 22 of

126

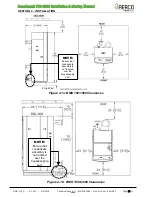

Figure 2-4b: BMK 1500/2000 and BMK 2500/3000 Supply and Return Locations

2.6.3 Dual Inlet Return Piping

The standard dual inlet connections

allow these units to be configured with a separate cooler

return temperature zone, rather than blending high and low return temperature zones. Utilizing

the dual return capability, these boilers can take further advantage of the condensing

capabilities. When configured with a lower return temperature zone or AERCO SmartPlate,

thermal efficiency can improve by up to 6% (Based on an 80 °F (26.7 °C) minimum return water

temperature at full fire. Lower return temperatures are possible which would yield even greater

efficiency gains. The maximum temperature differential across the boiler heat exchanger is 100

°F (37.8 °C).

To use the secondary inlet, pipe the

warmer

return water to the

secondary

(upper) inlet and

the

cooler

return water to the

primary

(lower) inlet. If the flow through both the primary and the

secondary return is constant, then the combined minimum flows must equal the specified

minimum flow of the boiler. If the flow through either of the inlet returns is intermittent, then the

minimum flow through one of the return connections must always equal the specified minimum

flow of the boiler. Contact your AERCO representative for additional information.

CONDENSATE DRAIN

HOT WATER

OUTLET

(SUPPLY)

SECONDARY

WATER INLET

(

WARMER

WATER RETURN)

AIR INLET

PRIMARY

WATER INLET

(

COOLER

WATER

RETURN)

EXHAUST MANIFOLD

BMK 1500/2000

BMK 2500/3000

2” NATURAL GAS OR

1” PROPANE INLET