Benchmark 750-3000 Installation & Startup Manual

SECTION 4

– INITIAL START-UP

OMM-115_D

•

GF-200

•

5/9/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 64 of

126

NATURAL GAS Combustion Calibration Instructions

15.

On Benchmark 3000 units

only

, once the manifold gas pressure is within the range in

table 4-1, record this value; it will be used later, in Section 5.2.2:

Low Pressure Gas Test

,

and Section 5.3.2:

High Pressure Gas Test

.

16.

Press the Down▼ arrow key until

SET Valve Position

appears on the display, then press

CHANGE

.

17.

Press the Up

▲ arrow key until the

SET Valve Position

reads

100%

, then press

ENTER

.

18.

With the valve position at 100%, insert the combustion analyzer probe into the exhaust

manifold probe opening (see Figure 4-2a or 4-2b in Section 4.2.3) and allow enough time

for the combustion analyzer reading to stabilize.

19.

Compare the

combustion analyzer’s oxygen readings to the O

2

Sensor value displayed in

the

Operating

menu on the C-More Controller. The offset value in the

Calibration

menu can

be adjusted by

±3%

to make the on-board O

2

sensor match the value from the combustion

analyzer. If the values differ by more than

±3%

and your combustion analyzer is correctly

calibrated, the on-board O

2

sensor may be defective and need to be replaced.

20.

Compare the measured oxygen level to the oxygen range shown in Table 4-2. Also, ensure

that the nitrogen oxide (NO

x

) and carbon monoxide (CO) readings do not exceed the

values shown in Table 4-2. If your target NO

x

value is 9 ppm or less, use the values in the

Ultra-Low NO

x

columns. If you are not

in a “NO

x

-

limited” area and/or do not have a NO

x

measurement in your analyzer, set the oxygen (O

2

) at

5.5% ± 0.5%

.

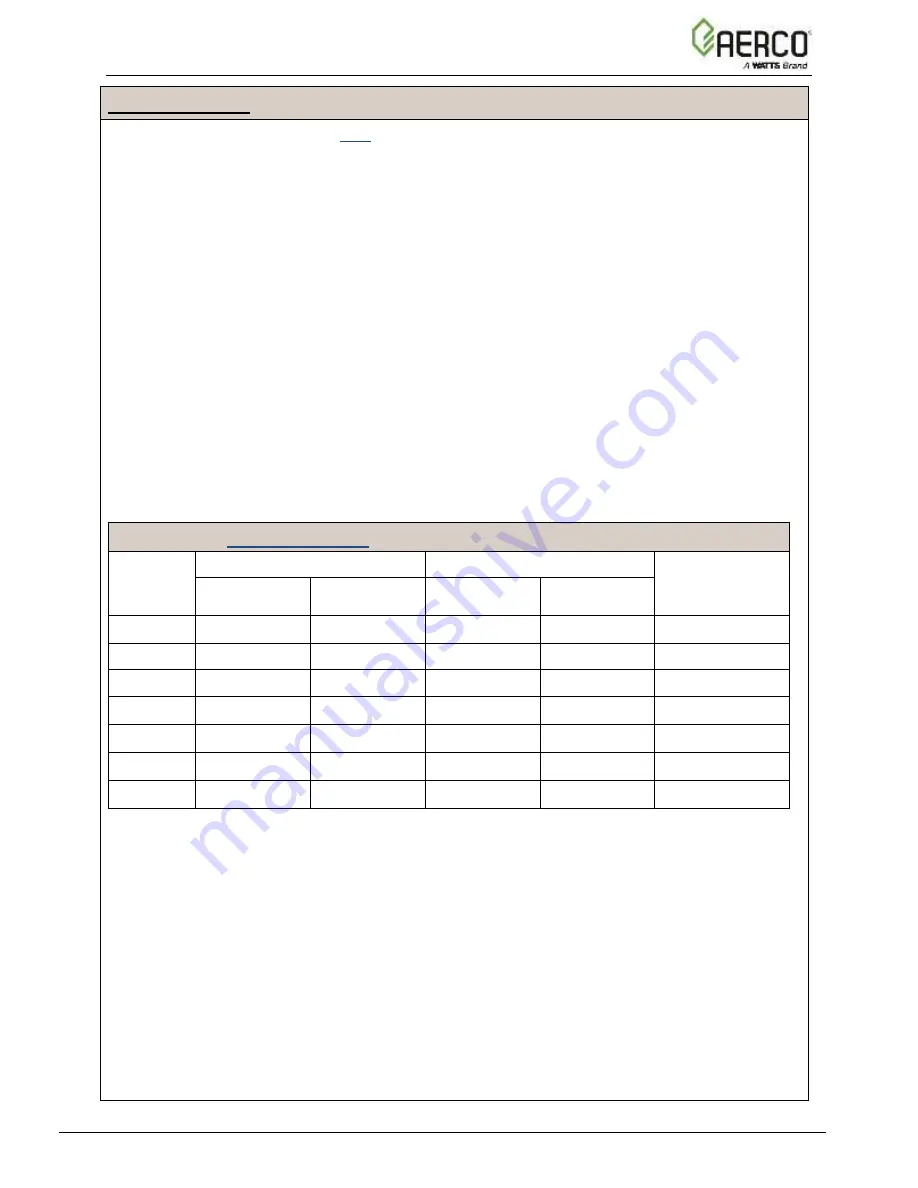

TABLE 4-2: NATURAL GAS Calibration Readings 100% Valve Position

Model

Standard NO

x

Ultra-Low NO

x

Carbon

Monoxide (CO)

Oxygen (O

2

)

%

Nitrogen

Oxide (NO

x

)

Oxygen (O

2

)

%

Nitrogen

Oxide (NO

x

)

750

5.5% ± 0.2%

≤20 ppm

6.0% ± 1.0%

≤9 ppm

<100 ppm

1000

5.5% ± 0.2%

≤20 ppm

6.0% ± 1.0%

≤9 ppm

<100 ppm

1500

5.2% ± 0.2%

≤20 ppm

5.7% ± 1.0%

≤9 ppm

<100 ppm

2000

6.0% ± 0.2%

≤20 ppm

6.0% ± 1.0%

≤9 ppm

<100 ppm

2500

5.6% ± 0.2%

≤20 ppm

-

-

<100 ppm

3000

5.1% ± 0.2%

≤20 ppm

-

-

<100 ppm

3000 DF

5.3% ± 0.2%

≤20 ppm

-

-

<100 ppm

21.

Next, press the Down ▼ arrow key until

CAL Voltage 100%

is displayed.

22.

Press the

CHANGE

key and observe that

CAL Voltage 100%

is flashing.

23.

The oxygen level at the 100% valve position should match the value in Table 4-2. Also,

ensure that the NO

x

and CO readings do not exceed the values in Table 4-2.

24.

If the oxygen level is not within

the specified range, adjust the level using the ▲ and ▼

arrow keys. This will adjust the output voltage to the blower motor as indicated on the

display. Pressing the Up

▲ arrow key increases the oxygen level and pressing the down

▼ arrow key decreases the oxygen level.

25.

Once the oxygen level is within the specified range at 100%, press the

ENTER

key to store

the selected blower output voltage for the 100% valve position. Record all readings on the

Combustion Calibration Sheets provided.