Benchmark 750-3000 Installation & Startup Manual

SECTION 4

– INITIAL START-UP

OMM-115_D

•

GF-200

•

5/9/2019

Technical Support

•

(800) 526-0288

•

Mon-Fri, 8 am - 5 pm EST Page 63 of

126

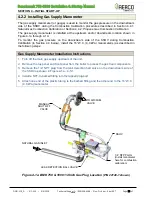

4.4.1 NATURAL GAS Combustion Calibration

NATURAL GAS Combustion Calibration Instructions

These instructions apply only to units running on

NATURAL GAS

. Instructions for doing

combustion calibration on a unit running PROPANE appear in the next section, 4.4.2.

1.

Open the water supply and return valves to the unit and ensure that the system pumps are

running.

2.

Open the

NATURAL GAS

supply valve to the unit.

3.

Set the C-

More Controller’s ON/OFF switch to the

OFF

position

4.

Turn external AC power to the unit

ON

. The display will show a description of the unit and

then the time and date.

5.

Press the

MENU

key on the front panel of the C-More Controller and access the

Setup

menu, enter the password

6817

and then press the

ENTER

key.

6.

Set the unit to the MANUAL mode by pressing the

AUTO/MAN

key. A flashing

Manual

Valve Position

message will be displayed with the present position in % and the

MANUAL

LED will light.

7.

Adjust the air/fuel valve position to

0%

by pressing the

▼ arrow key and then press

ENTER

.

8.

Ensure that the leak detection ball valve downstream of the SSOV is open and the

manometer is attached and functioning properly.

9.

Set

the

ON/OFF

switch

to

the

ON

position

.

10.

Press the

MENU

key on the front panel of the C-More Controller until

COMBUSTION CAL

MENU

appears on the display.

11.

Press the Up ▲ arrow key until

SET

Stdby V Out (Standby Voltage)

setting appears.

Verify that it is set to

2.0 V

(the default). AERCO recommends it be kept at 2.0 volts to

prevent flue gas recirculation. Individually vented units in positive pressure boiler rooms

may set

SET

Stdby V Out

to

0

volts.

12.

Press the Down

▼ arrow key until

SET Valve Position

appears, then press

CHANGE

.

13.

Use the Up ▲ arrow key to change the valve position to

30

%. The unit should begin its

start sequence and fire.

14.

Next, verify that the gas pressure downstream of the SSOV is set to the value in Table 4-1

for the model you are calibrating. If gas pressure adjustment is required, remove the brass

hex nut on the SSOV actuator to access the gas pressure adjustment screw (Figure 4-3).

Make gas pressure adjustments using a flat-tip screwdriver to obtain a gas pressure

approximately shown in Table 4-1.

TABLE 4-1: NATURAL GAS Gas Pressure Range @ 100% Fire Rate

Model

Single Fuel

Dual Fuel

BMK 750

2.0” ± 0.2” W.C. (0.50 ± 0.05 kPa)

-

BMK 1000

2.4” ± 0.4” W.C. (0.60 ± 0.10 kPa)

-

BMK 1500

3.6” ± 0.1” W.C. (0.90 ± 0.02 kPa)

3.6” ± 0.1” W.C. (0.90 ± 0.02 kPa)

BMK 2000

3.4” ± 0.2” W.C. (0.85 ± 0.05 kPa)

6.3” ± 0.1” W.C. (1.57 ± 0.02 kPa)

BMK 2500

2.0” ± 0.1” W.C. (0.50 ± 0.02 kPa)

5.8” ± 0.1” W.C. (1.44 ± 0.02 kPa)

BMK 3000

2.1” ± 0.2” W.C. (0.52 ± 0.05 kPa)

6.0” ± 0.2” W.C. (1.49 ± 0.05 kPa)