CLS200 Series User’s Guide

Chapter 7: Turning and Control

133

Proportional and Integral Control

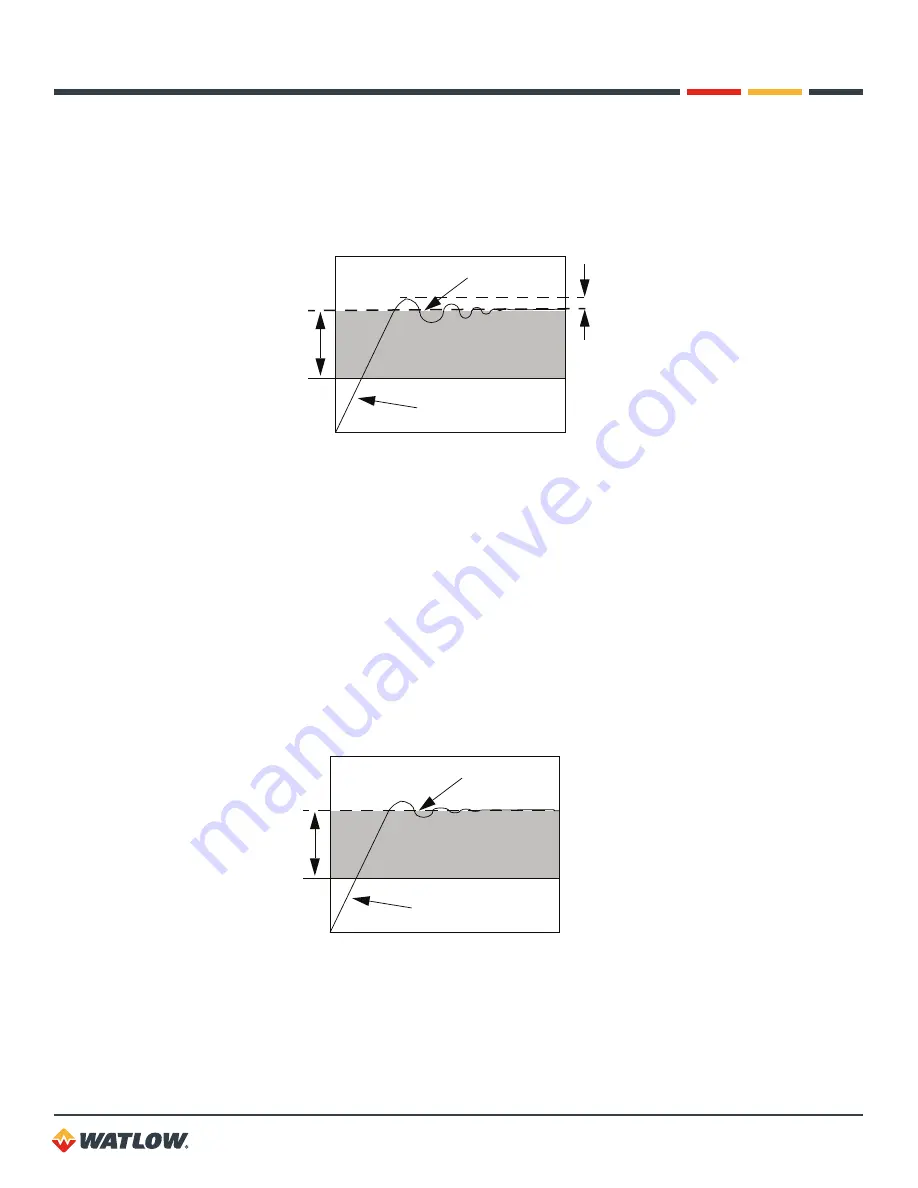

With proportional and integral control, the integral term corrects for offset by repeating the

proportional band’s error correction until there is no error. For example, if a process tends to settle

about 5°F below the setpoint, appropriate integral control brings it to the desired setting by gradually

increasing the output until there is no deviation.

Proportional

Setpoint

Process Variable

Band

Over-

shoot

Figure 7.3

— Proportional and Integral Control

Proportional and integral action working together can bring a process to setpoint and stabilize it.

However, with some processes the user may be faced with choosing between parameters that

make the process very slow to reach setpoint and parameters that make the controller respond

quickly, but introduce some transient oscillations when the setpoint or load changes. The extent to

which these oscillations of the process variable exceed the setpoint is called

overshoot

.

Proportional, Integral and Derivative Control

Derivative control corrects for overshoot by anticipating the behavior of the process variable and

adjusting the output appropriately. For example, if the process variable is rapidly approaching the

setpoint from below, derivative control reduces the output, anticipating that the process variable will

reach setpoint. Use it to reduce overshoot and oscillation of the process variable common to PID

control.

Figure 7.4

shows a process under full PID control.

Proportional

Setpoint

Process Variable

Band

Figure 7.4

— Proportional, Integral and Derivative Control