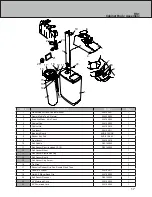

RS1

Service Instructions / Instructional Videos Available at www.csiwater.com

F.

To Replace Seals and Spacers

1. Follow steps

A1 - A3

.

2. Remove the control top cover. Disconnect the meter signal wire from the meter.

3. Remove screw and washer at piston drive yoke. Remove powerhead mounting screws.

The entire powerhead assembly will now lift off easily. Remove piston retaining plate

screws.

4. Pull upward on end of piston rod yoke until assembly is out of valve. Remove seals and

spacers. (Note: Special end spacer must be reused)

5. Lubricate new seals with silicone lubricant included in the seal and spacer kit. Make

sure the special end spacer is properly seated in the valve body. Install new seals and

spacers individually, pressing around the outer edge of each seal to make sure it is

seated.

(When all seals and spacers are seated properly, you will have a 1/4” of space between

the top seal the the top of the valve body)

6. Follow Steps

E7 - E10

.

G.

To Replace Meter

1. Follow steps

A1 - A3

2. Remove two screws and clips at bypass valve or yoke. Pull softener tank away from

plumbing connections.

3. Remove meter cable from meter.

4. Remove two screws and clips at meter and pull the meter out of the control valve.

5. Apply silicone lubricant to O rings on new meter.

6. Attach meter to control valve. Note: meter portion of module must be assembled on

valve outlet. Install two screws and clips.

7. Plug meter cable into new meter.

8. Attach two clips and screws at bypass valve or yoke. Be sure clip legs are firmly

engaged with lugs.

9. Follow steps

D9 - D14.

21