RS1

PLEASE NOTE THESE SPECIFICATIONS BEFORE PROCEEDING

OPERATING PRESSURE RANGE : 20 - 125 PSI

OPERATING TEMPERATURE RANGE : 33º F - 120º F

INLET / OUTLET PIPE SIZE : 3/4: FNPT

PLEASE COMPLY WITH ALL APPLICABLE PLUMBING CODES

PROTECT THE SOFTENER AND PIPING FROM FREEZING TEMPERATURES

Please read the entire Owner’s Manual and Instruction before installation.

This Owner’s Manual must stay with the unit.

-How A Water Softener Works-

Water hardness is derived from Calcium and Magnesium minerals that have been dissolved into the water under

the earth’s surface. These minerals are found in limestone deposits and are the source of hard water. The amount

of hardness in a given water supply is dependent upon the quantity of Calcium and Magnesium present and the

length of time water has been in contact with them. This can vary dramatically from well-to-well and, for this reason,

a water analysis is imperative in order to determine the proper treatment method. The degree of hardness increas-

es as the concentration of Calcium and Magnesium “ions” increase and is measured in

Grains Per Gallon (gpg).

The problem of hard water in the home / business comes to light in many facets of daily use. Water spots and scum

left behind on bathtubs, fixtures and showers; wear and tear on appliances; calcium build-up in hot water heaters

and piping; and, greater amounts of soap and detergents being used are just a few examples.

The modern water softener is designed to reduce hardness ions and their unpleasant side effects. Special resin

beads in the softener mineral tank are used to change hard water into soft water. The surfaces of these beads are

covered with sodium ions. As hard water enters the mineral tank and comes into contact with the resin, an ex-

change of ions takes place as dissolved Calcium and Magnesium ions cling to the resin surface and sodium ions

take their place, thus softening the water. This process is called

Ion Exchange

. Over time, the sodium ions used

for the exchange process become depleted and must be replenished.

The water softener provides a

Regeneration

process whereby brine solution enters the mineral tank, driving-off

the collected hardness ions and replenishes the surface of the resin beads with more sodium ions. This process is

automatically initiated by the control valve on the mineral tank. The regeneration process has five basic cycles as

follows:

1.

Backwash

- The control valve directs the water flow in a reverse direction through the mineral tank, separating

the resin beads and flushing any accumulated particles to a waste drain.

2.

Brine & Rinse

- In the first part of this cycle, the control valve directs brine solution downward through the

mineral tank, driving-off collected hardness ions and replenishing the resin beads with sodium ions. The second

part of the cycle rinses hardness ions and excess brine from the mineral tank to the waste drain.

3.

Rapid Rinse

- The control valve directs the water flow downward, settling and recompacting the resin bed.

4.

Brine Refill

- The control valve directs fresh water into the salt compartment to create new brine solution for the

next scheduled regeneration.

5.

Service

- This is the normal “operating” cycle where hard water enters the mineral tank, comes into contact with

the resin beads and exchanges hardness ions for sodium ions - the water then becomes “soft” and ready for

use.

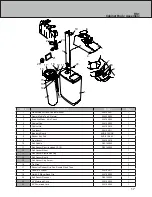

Softener Specifications

4